Solubilization of Resins into solvents and oils

Resins are used in a wide range of products, for example varnishes, adhesives, inks and paints, surface coatings, laminates and sealants.

The Process

Resins can be supplied in liquid, powder, and solid or “chip” form and due to this and the range of the end products, manufacturing processes vary widely. Typical process requirements may include:

- Where liquid resins are used, the mixing system must be capable of blending two liquids of widely different viscosity, because liquid resins can be highly viscous. Inadequate mixing can lead to stratification where globules of resin remain undiluted in the solvent.

- With both powdered and solid resins, the mixing system must provide adequate in-tank movement to prevent the resin from sticking to the vessel walls or sinking to the bottom of the tank.

- Vigorous agitation is required to get the resin to dissolve into the surrounding liquid.

- Heating is usually required to aid the solubilization process.

The Problem

If you are using conventional mixing methods to process the resin the following problems can arise:

- Liquid resin is simple to use but costly. Likewise, powdered resins can be easier to dissolve than solid or chip forms but the additional raw material processing costs are passed on to the user.

- Even at high temperatures, conventional agitators cannot easily dissolve solid resin. An agitator simply moves the resin around the tank, only dissolving the outer layer of the chips. This slowly reduces the chips down but it can take hours to complete solubilization.

- Processing at raised temperatures further adds to processing times and costs.

- Other raw materials, particularly powders such as fillers and thickening agents can form agglomerates when added to the mixture. An agitator does not have the shear energy necessary to disperse them once they have formed.

- Poor in-tank movement can allow the resin to form an agglomerated mass on the base of the vessel which conventional agitators cannot disperse, leading to wastage and increased cleaning requirements.

The Solution

Silverson Machines refers to the process of disintegrating and solubilizing solid resins into solvents as ‘Cold Cutting’ because unlike conventional mixing methods, with a Silverson mixer, solid resins can be rapidly solubilized at ambient temperature. Here’s how it works:

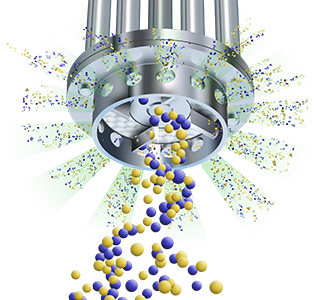

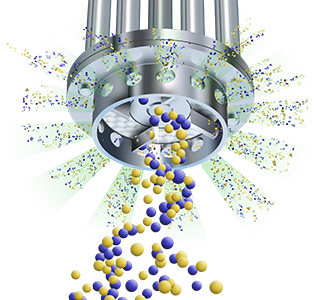

Stage 1

The resin is added directly into the solvent or oil without the need for pre-heating and the mixer is started. The high-speed rotation of the rotor creates a powerful suction drawing the resin and solvent into the workhead.

Stage 2

The chips are disintegrated as they are forced out through the holes in the stator and projected back into the vessel, rapidly reducing them down to a fine particle size. This maximizes the surface area exposed to the solvent.

Stage 3

The intense mixing means that all the contents of the vessel pass through the workhead many times in a short mixing cycle, accelerating the solubilization process. The batch is completed in a matter of minutes.

-

Stage 1

Stage 1

The resin is added directly into the solvent or oil without the need for pre-heating and the mixer is started. The high-speed rotation of the rotor creates a powerful suction drawing the resin and solvent into the workhead.

-

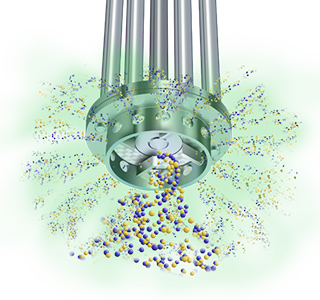

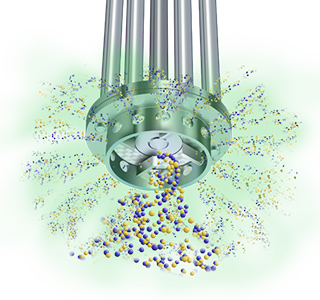

Stage 2

Stage 2

The chips are disintegrated as they are forced out through the holes in the stator and projected back into the vessel, rapidly reducing them down to a fine particle size. This maximizes the surface area exposed to the solvent.

-

Stage 3

Stage 3

The intense mixing means that all the contents of the vessel pass through the workhead many times in a short mixing cycle, accelerating the solubilization process. The batch is completed in a matter of minutes.

The Advantages

- Processing times can be reduced from hours to just minutes.

- The process can be carried out at ambient temperature, further reducing process times and costs.

- A Silverson mixer can also be used for the addition of other raw materials including oils and liquid dispersions and a wide range of powders – even difficult materials such as aerosil.

- For aqueous systems, a Silverson mixer can be used to create stable emulsions.

- Shorter process time reduces solvent emissions.

Silverson offer mixers for production on a small or large scale, meaning you can easily scale up from the lab to full production.

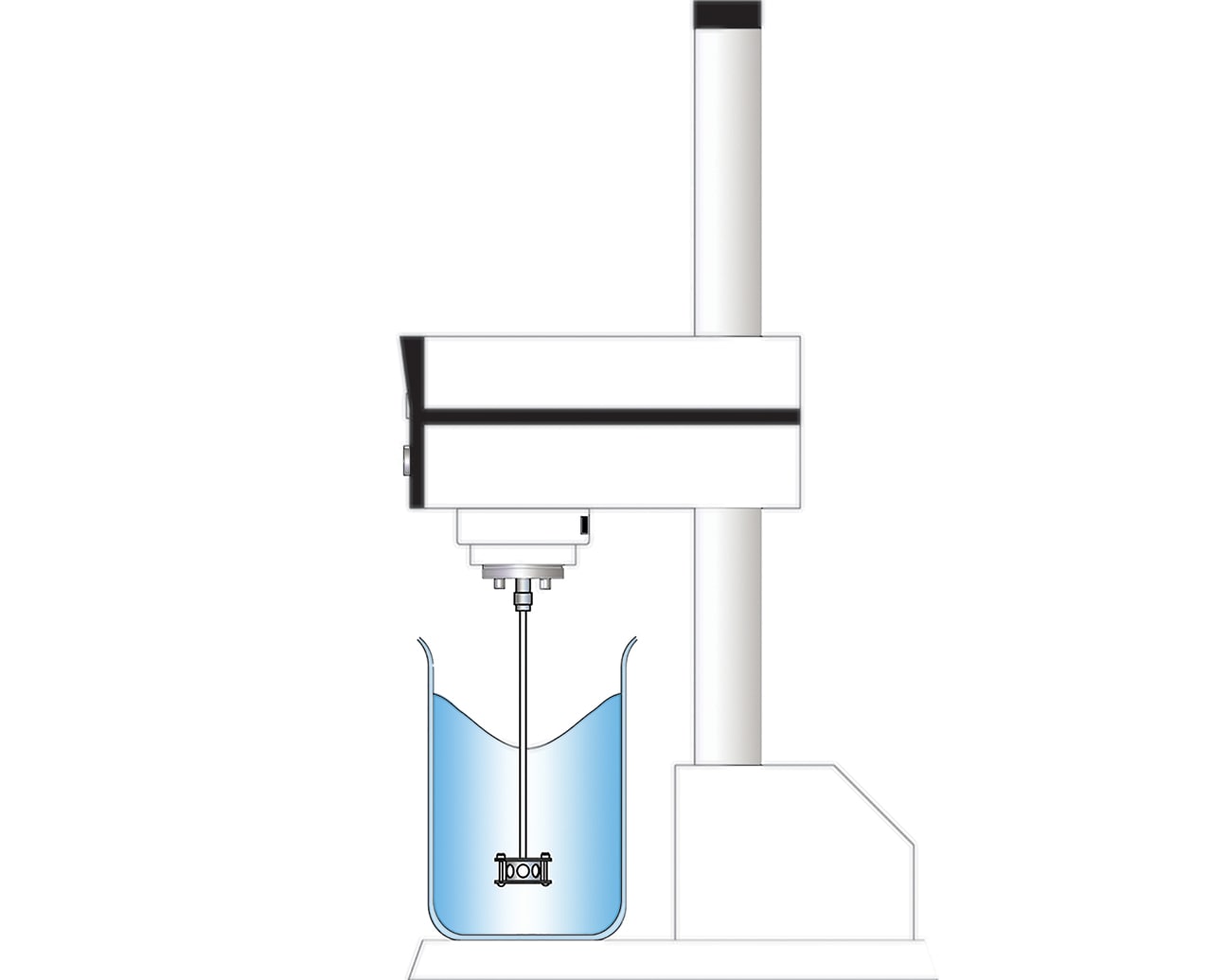

Laboratory Mixers

- Ideal for smaller batches and R&D work

- Suitable for batch sizes of up to 12 liters

- Interchangeable workheads allow the unit to be adapted for a range of laboratory applications

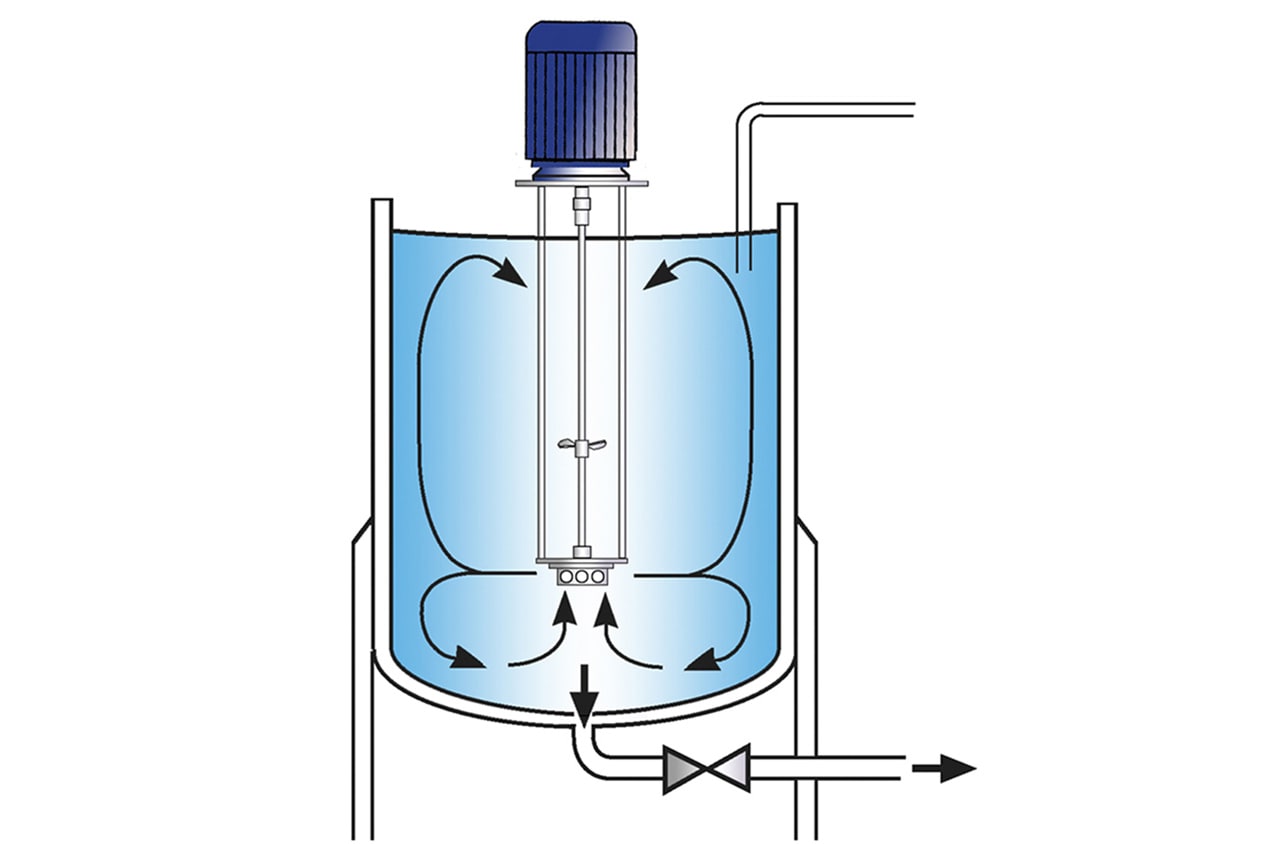

High Shear Batch Mixers

- Suitable for batches of up to 400 US gallons

- Can be used on mobile floor stands or mounted in closed vessels

- Minimum maintenance

- Small units available for R&D and pilot production

- Units available for Explosion Proof or Hazardous Duty areas

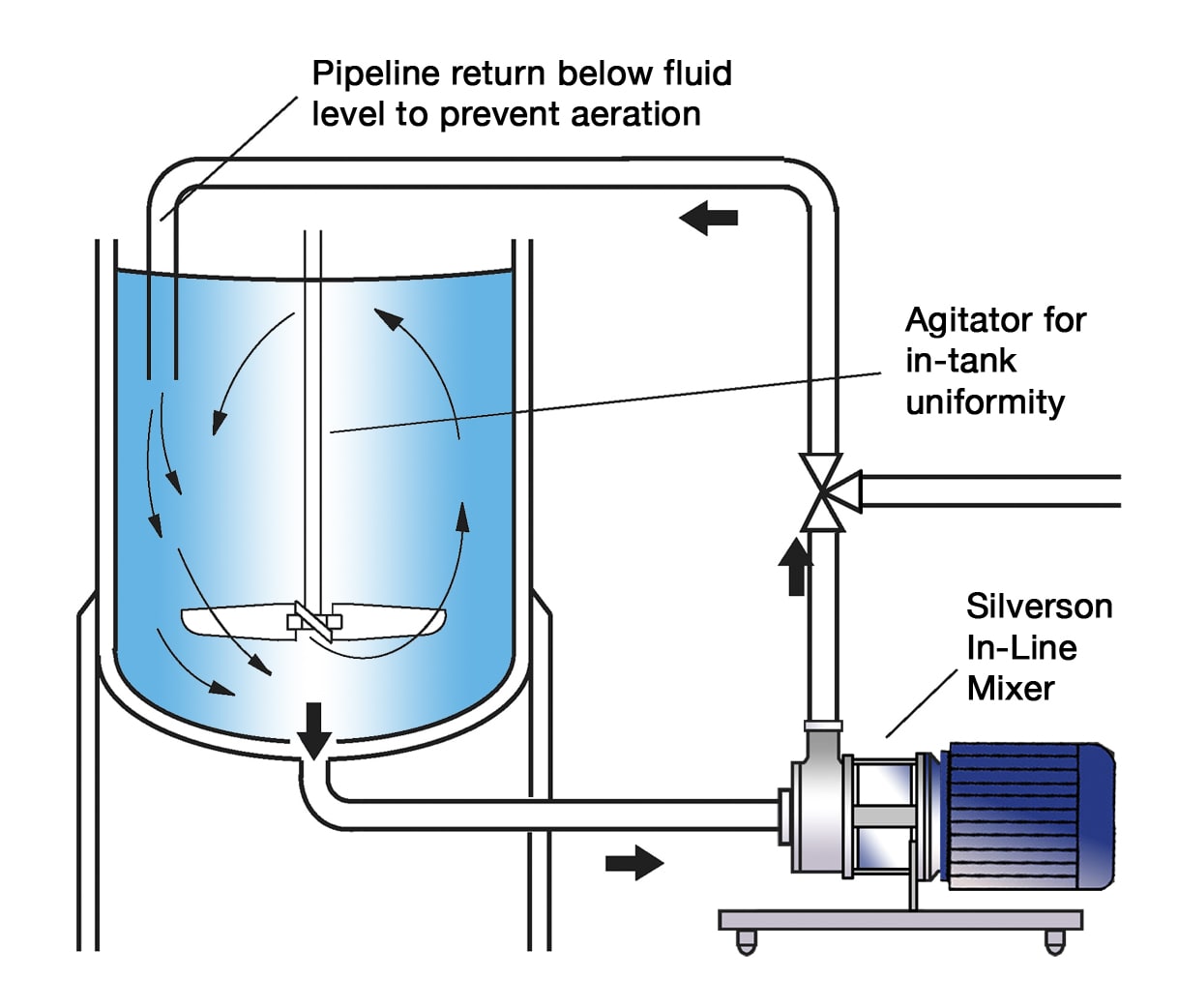

High Shear In-Line Mixers

- Ideal for larger batches

- Self-pumping

- Easily retrofitted to existing plant

- The In-Line mixers’ effort is concentrated on the small volume of material inside the workhead rather than circulating the contents of the vessel, a more energy-efficient process

- Units available for Explosion Proof or Hazardous Duty areas

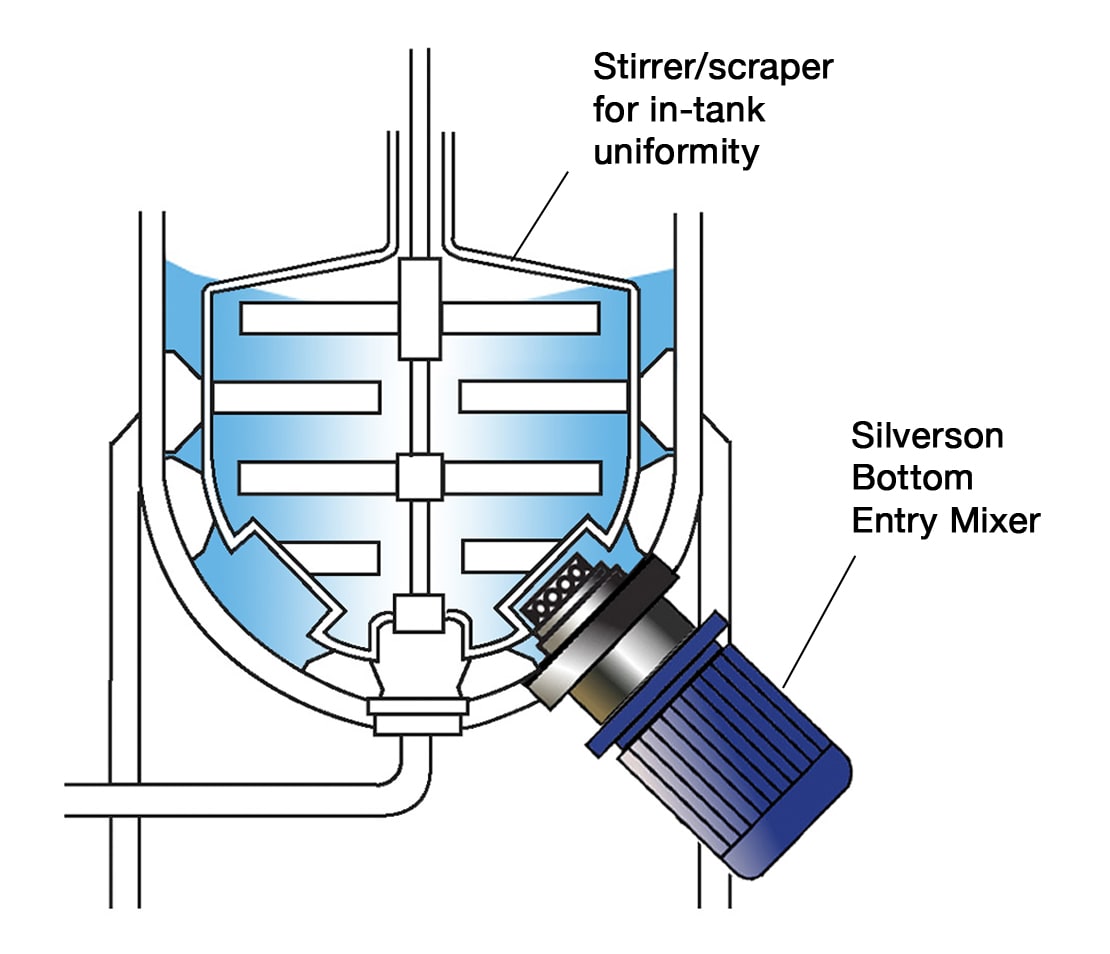

High Shear Bottom Entry Mixers

- May be used in conjunction with an anchor stirrer/scraper to maintain in-tank uniformity with very large volumes or higher viscosity mixes

- Can be used with a Silverson In-Line mixer to further accelerate solubilization, particularly with larger solids

- Units available for Explosion Proof or Hazardous Duty areas