High Shear Mixers: The Powerful Solution for Your Mixing Needs

From laboratory to production-scale, Silverson Machines offers an unparalleled range of high shear mixers. Guided by our commitment to innovation, reliability, and customer satisfaction, we are dedicated to equipping you with the optimal mixing solution tailored to your unique requirements.

What is high shear mixing?

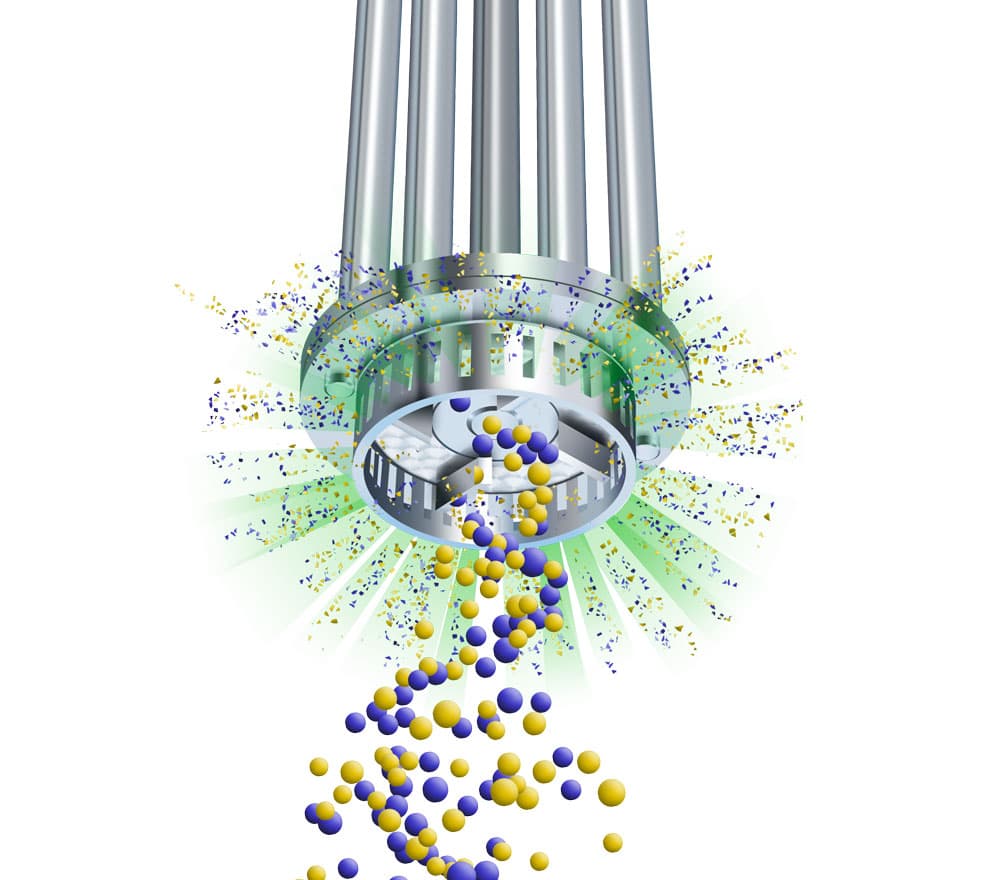

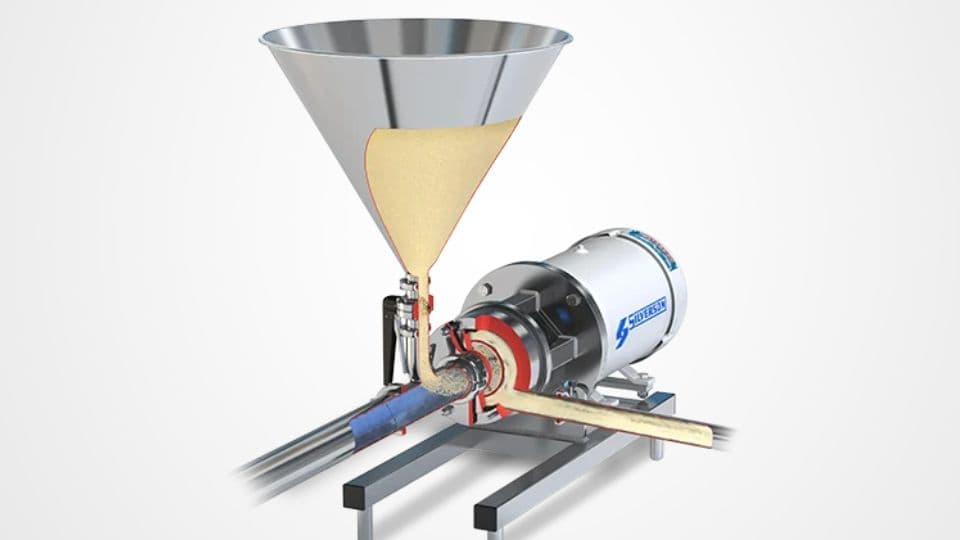

High shear mixing is an advanced mixing technique that involves intense mechanical agitation and shearing forces to achieve superior blending, dispersion, and particle size reduction. Unlike conventional mixers or agitators, high shear mixers utilize specialized rotor/stator technology to generate extremely high shear rates, creating a powerful suction effect that continuously draws materials into the high shear zone.

Leveraging this advanced technology, high shear mixers provide remarkable mixing efficiency, enabling:

- Faster processing times and increased production throughput.

- Finer and more uniform droplet/particle size distributions.

- Improved product quality, consistency, and stability across batches.

Silverson high shear mixers are engineered to deliver exceptional mixing performance, combining advanced rotor/stator technology with robust construction and scalable designs.

Comprehensive Range of High Shear Mixers

Engineered with precision and built to last, each Silverson high shear mixer is meticulously crafted to deliver industry-leading mixing performance, seamlessly tackling tasks from small bench-top applications to large-scale production demands.

Browse by Product Line

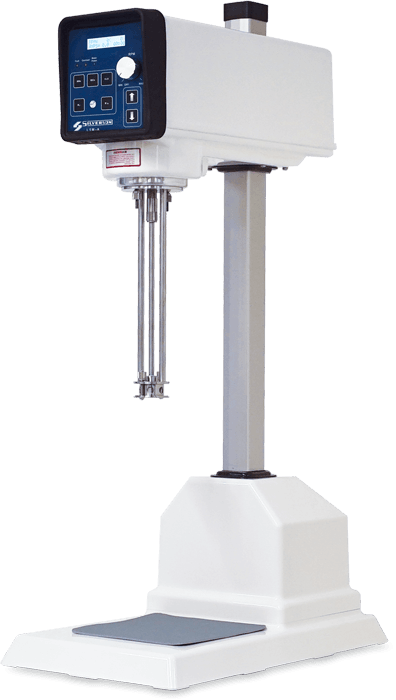

Lab Series

Ideal for laboratory work and R&D

Laboratory MixersLaboratory In-Line Mixers

Laboratory Powder/Liquid Mixer

Batch Series

Mix, emulsify, homogenize, disintegrate and dissolve

Batch MixersPilot Scale Batch Mixers

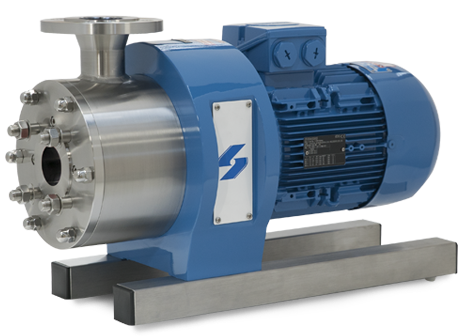

In-Line Series

Reduce mixing times by up to 90%

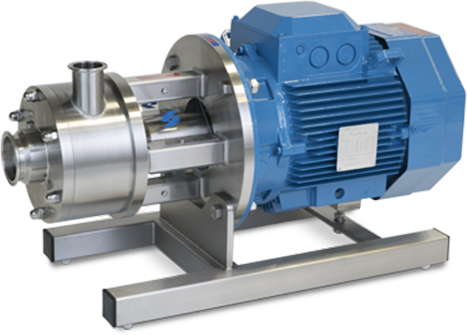

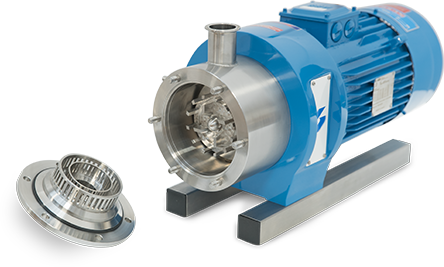

In-Line MixersHigh Viscosity In-Line Mixers

In-Line Ultra Sanitary Mixers

Powder/Liquid Mixers

Quickly disperse and hydrate powders, even at higher viscosities

Flashmix Powder/Liquid MixersFlashblend Powder/Liquid Mixing Systems

Laboratory Powder/Liquid Mixer

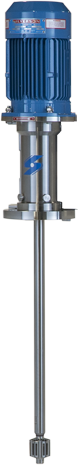

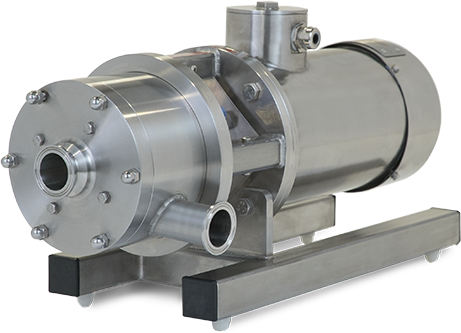

Bottom Entry Mixers

Ideal for disintegrating solids and incorporating powders

Bottom Entry MixersDisintegrator/Dissolvers

Additional Mixers

Improving product quality & consistency

Silverson Mixer HomogenizersUltramix Mixers

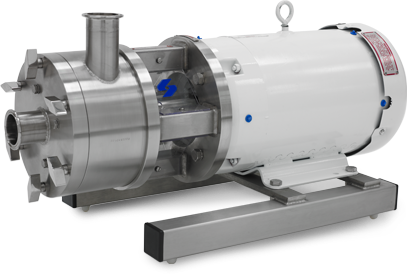

Sanitary Mixers

All Mixers

High Shear Mixing FAQs

Q: Why use a high shear mixer rather than an agitator?

A: Simple agitators are great for basic mixing tasks like liquid-liquid blending or mixing similar viscosity materials. However, for more demanding applications, a high shear mixer offers significant advantages:

- Superior Mixing Power: High shear mixers use intense force to break down particles, create emulsions, and achieve a uniform dispersion. Simple agitators primarily stir, which is not effective for these tasks.

- Finer Particle Size: High shear creates powerful shearing forces that break down particles to much smaller sizes compared to agitators. This can be crucial for processes like homogenization and creating stable emulsions.

- Faster Processing Times: The intense mixing action of high shear mixers significantly reduces processing times compared to agitators. This translates to increased efficiency and production output.

- Wider Range of Applications: High shear mixers can handle a broader range of viscosities, from low-viscosity liquids to highly viscous pastes. Agitators struggle with thicker materials.

Put simply, if you need to achieve a finer mix, faster processing, or work with diverse viscosities, a high shear mixer is the superior choice.

Q: What are the key advantages of using Silverson high shear mixers?

A: Silverson high shear mixers offer several benefits, including:

- Unmatched Versatility: The Silverson approach offers unparalleled flexibility, allowing a single machine to perform the duties that previously required multiple pieces of process equipment. This versatility streamlines operations and eliminates the need for dedicated agitators, emulsifiers, homogenizers, and dispersers.

- Effortless Scale-Up: Silverson laboratory and small-scale mixers are designed and built to the same tolerances as production units, ensuring a smooth transition from R&D to full-scale manufacturing with consistent results.

- Durable Construction: Our mixers are built to last, ensuring reliable performance in demanding production environments.

Q: How do I select the right Silverson high shear mixer for my application?

A: To ensure you get the ideal mixer for your needs, consider these key factors:

- Batch size: Select a mixer with a capacity that meets your typical batch volume requirements.

- Product viscosity: Choose a mixer with sufficient power and design features suitable for the viscosity of your product.

- Desired droplet/particle size: The required final size of droplets or particles will influence the specific rotor-stator workhead design and operating parameters needed.

For further guidance, consult with Silverson’s experts. We can assist you in selecting the optimal equipment, evaluating different mixing geometries, and determining the proper scale-up approach for your specific needs.