Preparation of Paper Coatings

Paper coatings impart a variety of properties, both decorative (whiteness, opacity, etc.) and functional (smoothness, absorption rate, etc.) A typical coating has two principle constituents: a dispersion of pigments in water and an adhesive or binder.

Traditionally coatings were based on clays such as china clay (kaolin) and bentonite, however, in modern paper coatings calcium carbonate is more common. Other materials are also used to obtain certain properties. These include:

- Talc - for smoothness.

- Silica - for applications requiring good water absorption rate - e.g. ink jet paper.

- Titanium Dioxide - for whiteness and opacity.

- Resins - control of ink absorption rate.

The Process

The clay or other pigment is normally supplied in bulk tankers as slurry containing 60% solids. Some paper manufacturers prepare the slurry themselves, dispersing the powder into water with conventional agitation. This is a relatively simple duty, however long mixing times may be required to produce each batch. Basic coating preparation can be summarized as follows:

- The slurry is diluted to the required working strength and held in a storage tank.

- The binder is prepared separately before being blended with the slurry.

- Other additives such as waxes, coloring, etc. may be added at this stage.

- The finished coating may be passed through a filter to remove agglomerates or impurities.

- The coating is then applied to the paper or board by a number of methods.

The Problem

- Agglomerates and impurities present in the clay slurry are not broken down by agitation.

- These transfer to the paper coating machine and result in defects (e.g. holes) in the coating surface.

- Removal of agglomerates by filtration leads to reduced yield and increased waste, process time and costs.

The Solution

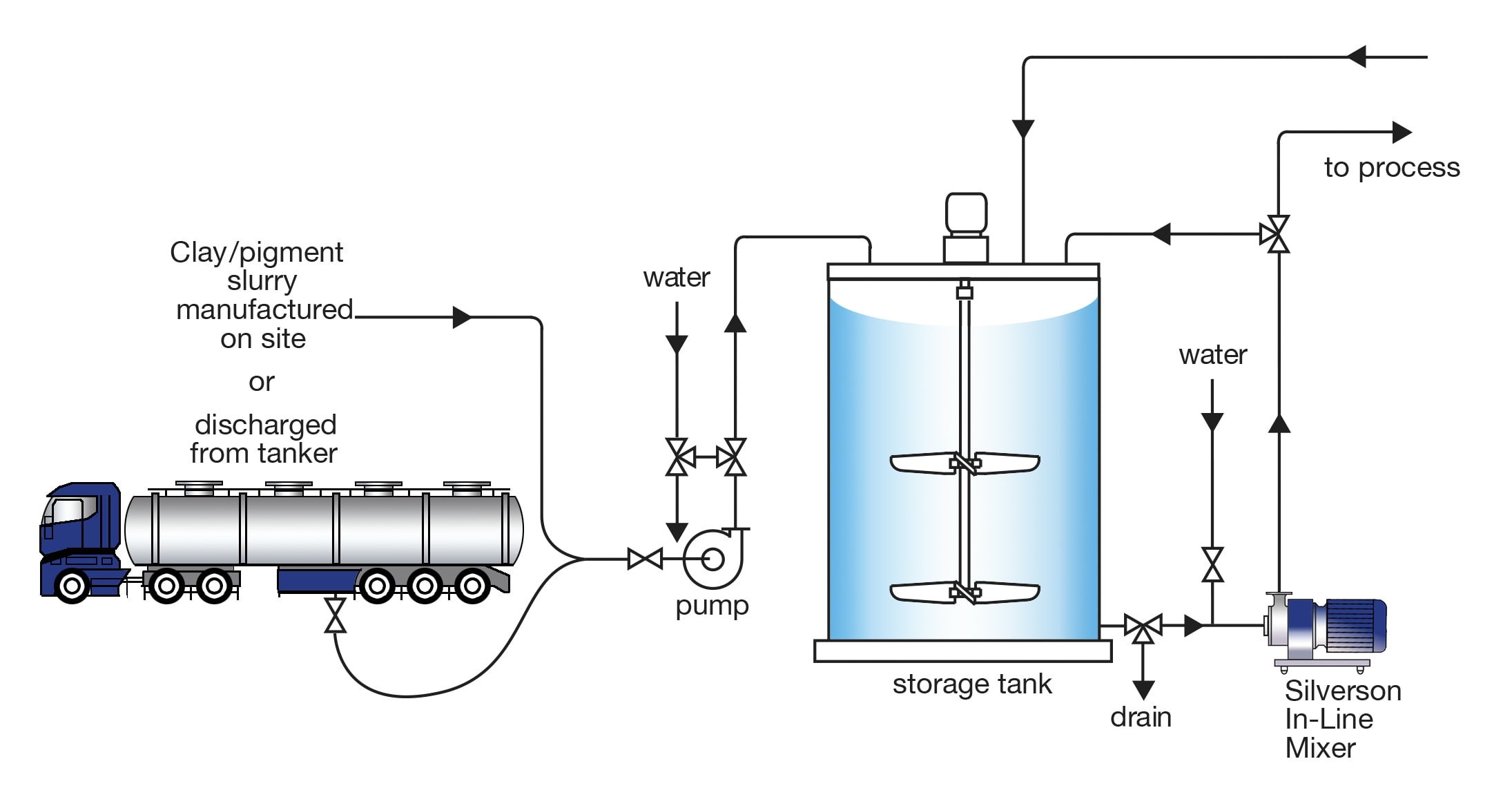

A Silverson In-Line mixer can be added to a typical slurry handling system as shown.

A single pass through the rotor/stator workhead subjects the slurry to intense high shear, ensuring that the product fed to the coating plant is agglomerate-free. Similarly an In-Line mixer can be used in a recirculation system to accelerate the dispersion process and produce an agglomerate-free slurry in a fraction of the time taken by agitation alone.

This is achieved by the 3 stage mixing cycle of the Silverson rotor/stator workhead. Operation is as follows:

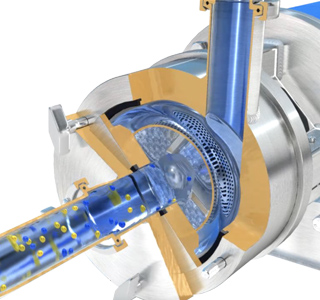

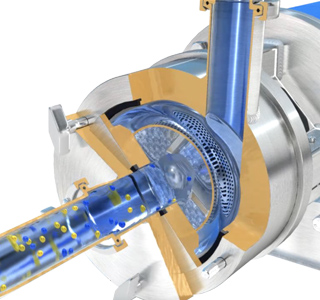

Stage 1

The slurry is drawn into the rotor/stator workhead and is driven to the periphery of the head by centrifugal force.

Stage 2

Agglomerates are subjected to a milling action in the clearance between the tips of the rotor blades and the inner wall of the stator.

Stage 3

This is followed by intense hydraulic shear as the product is forced out through the stator and pumped downstream to the next processing stage.

-

Stage 1

Stage 1

The slurry is drawn into the rotor/stator workhead and is driven to the periphery of the head by centrifugal force.

-

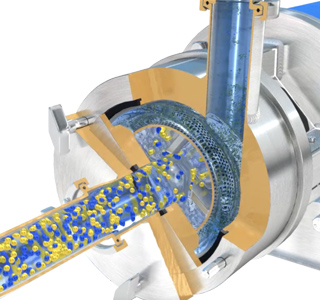

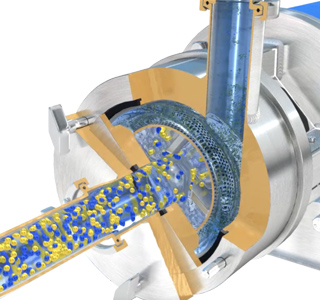

Stage 2

Stage 2

Agglomerates are subjected to a milling action in the clearance between the tips of the rotor blades and the inner wall of the stator.

-

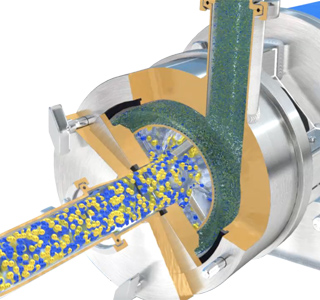

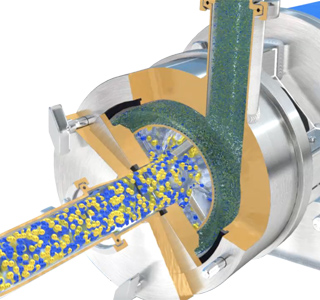

Stage 3

Stage 3

This is followed by intense hydraulic shear as the product is forced out through the stator and pumped downstream to the next processing stage.

The Advantages

- Agglomerates are completely broken down in a single pass.

- Easily retrofitted to existing plant.

- Filtration is not required.

- Aeration free.

- Self-pumping.

- Can be used to discharge vessel, depending on product viscosity.

- Reduced waste.

- Increased yield.

- Can be used to blend other additives including binders/adhesives.

- Small units available for R&D and pilot production.

- High Viscosity models available.