Overcoming Challenges in Mustard Manufacturing

Mustards are made in a variety of forms, with various flavors and textures. They can however be divided into two basic categories:

- Smooth mustards, which are normally made from finely ground mustard powder (“mustard flour”).

- Coarse grain or whole grain mustards, which, as the name suggests, consist of partially ground or unmilled mustard seed.

In each case, the mustard would contain vinegar, water or a mixture of the two. A number of other ingredients may be added, including sugar, salt, various flavors such as honey, herbs, spices and coloring such as turmeric. Some products also contain antioxidants and an acidity regulator e.g. citric acid. The starches contained in the mustard seed provide the desired thickening effect, however some recipes may contain additional thickening agents such as wheat flour.

The Process

The manufacturing process varies according to the type of mustard being produced.

Normally some form of grinding is required in the preparation process, either to produce the mustard powder from seed, or to break down the seed in order to release the starches and obtain the thickening effect. The process can be summarized as follows:

- A smooth mustard is produced by dispersing mustard flour and other ingredients into water, or a mixture of water and vinegar, and mixing until homogeneous.

- Coarse grain mustard can be manufactured in several stages. The mustard seed would first be either pre-soaked in the vinegar (typically overnight) or pre-mixed with other dry ingredients before being added to the vinegar. The product is then ground (traditionally in stone mills) to the required consistency.

- Coarse grain mustards can also be produced by disintegrating mustard seed into a finished smooth mustard to give a textured product.

The Problem

There are several limitations in using conventional agitators for this process:

- When dispersing mustard flour into water/vinegar, agglomerates can easily form. Agitators do not produce sufficient shear to rapidly break these down.

- Maximizing the thickening effect of the mustard (and other thickening additives, where used) is difficult to achieve using traditional methods.

- Powder addition must be carried out at a controlled rate to reduce agglomerates.

- Long mixing times are required to complete dispersion/hydration.

- Stone milling is a slow process.

- Mustard seed would normally require pre-milling to break it down before being added to a finished smooth mustard, as an agitator cannot disintegrate the seed.

The Solution

A Silverson mixer can overcome these problems. The high shear mixing action can produce an agglomerate-free dispersion of powders when producing smooth mustards, and can break down and disperse mustard seed in a finished smooth mustard to produce a coarse grain texture. Conventional milling of whole grain or coarse grain mustards can be carried out at a faster rate by pre-processing the mix using a Silverson. Operation is as follows:

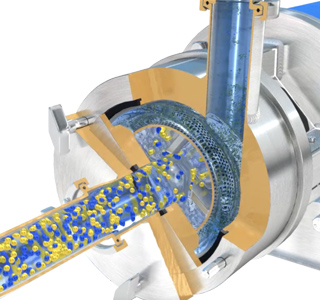

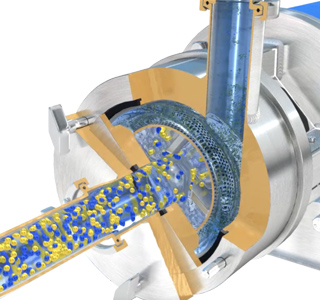

Stage 1

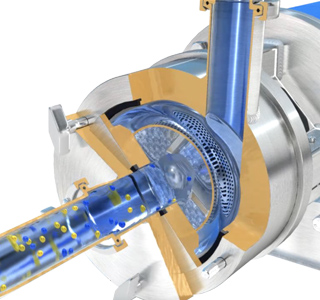

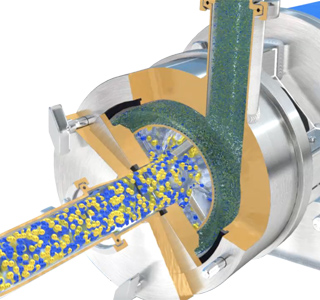

The high speed rotation of the rotor creates a powerful suction which draws the liquid and solid/powdered ingredients into the mixing zone. The materials are the subjected to intense shear in the confined area of the workhead.

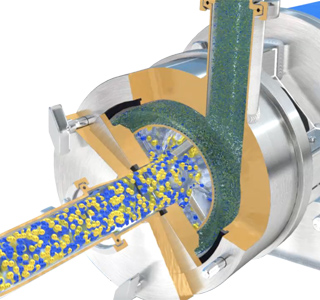

Stage 2

Mustard seed and any agglomerates in the powdered ingredients are broken down in the gap between the rotor blades and stator wall. The product is forced out of the stator and projected radially back into the mix.

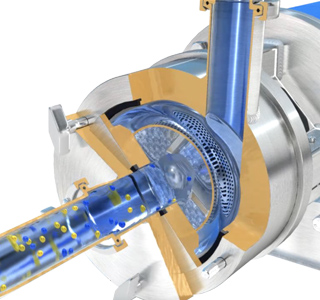

Stage 3

Simultaneously, fresh material is drawn into the workhead, setting up a circulatory mixing pattern which progressively reduces particle size. In a short mixing cycle all the material passes through the workhead, ensuring a uniform product is obtained.

-

Stage 1

Stage 1

The high speed rotation of the rotor creates a powerful suction which draws the liquid and solid/powdered ingredients into the mixing zone. The materials are the subjected to intense shear in the confined area of the workhead.

-

Stage 2

Stage 2

Mustard seed and any agglomerates in the powdered ingredients are broken down in the gap between the rotor blades and stator wall. The product is forced out of the stator and projected radially back into the mix.

-

Stage 3

Stage 3

Simultaneously, fresh material is drawn into the workhead, setting up a circulatory mixing pattern which progressively reduces particle size. In a short mixing cycle all the material passes through the workhead, ensuring a uniform product is obtained.

The Advantages

- Agglomerate-free mix.

- Consistent product quality and repeatability.

- Rapid mixing times.

- Varying degrees of particle size reduction can be obtained as required by selection of the appropriate workhead or stator screen.

- Pre-processing the mustard with a Silverson prior to milling provides an optimum pre-mix which the conventional mill will process at a much faster rate, reducing the number of passes required.

The batch size, formulation, type of ingredients and the viscosity of the end product dictates which machine from the Silverson product range is suited to individual processing requirements:

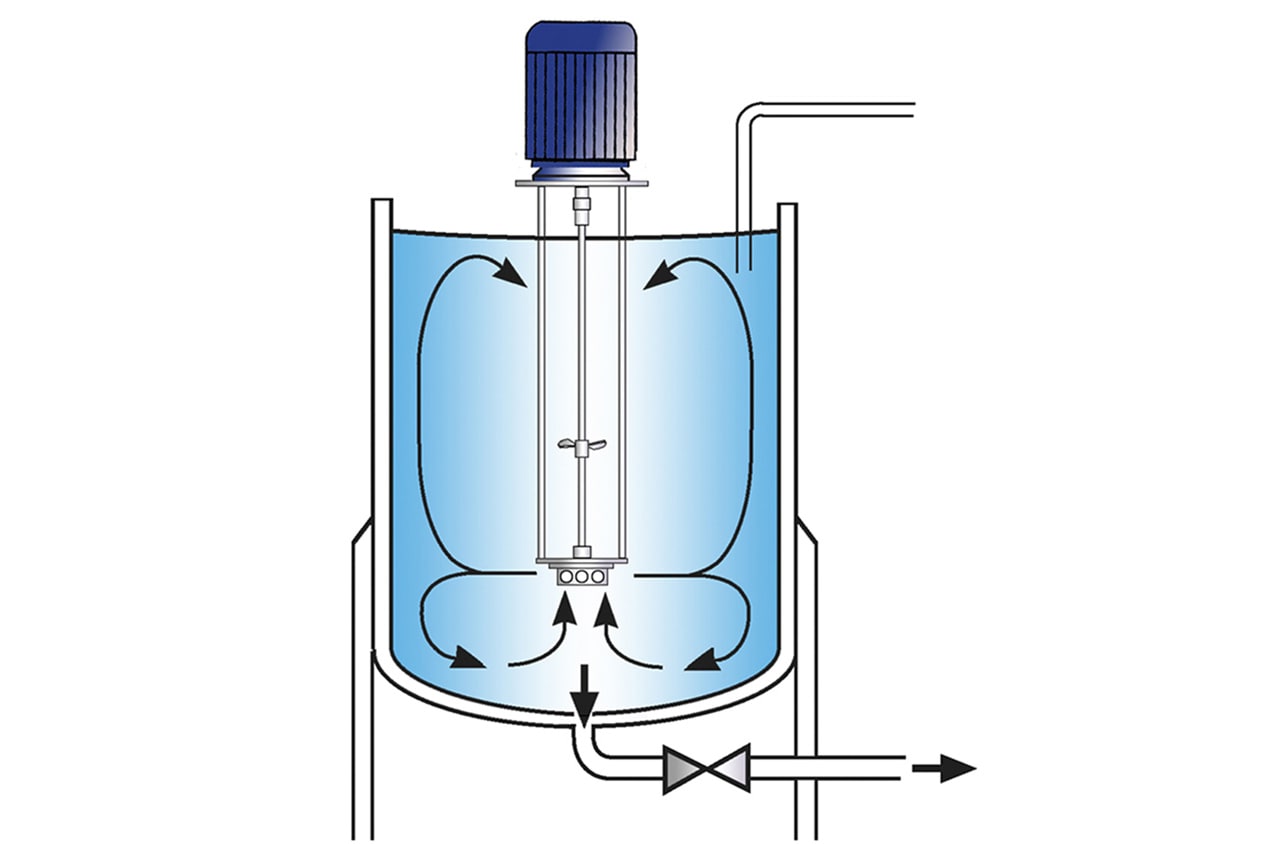

High Shear Batch Mixers

- Suitable for small batches up to 50 - 80 US gallons

- Ideal for manufacture of specialty mustards

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

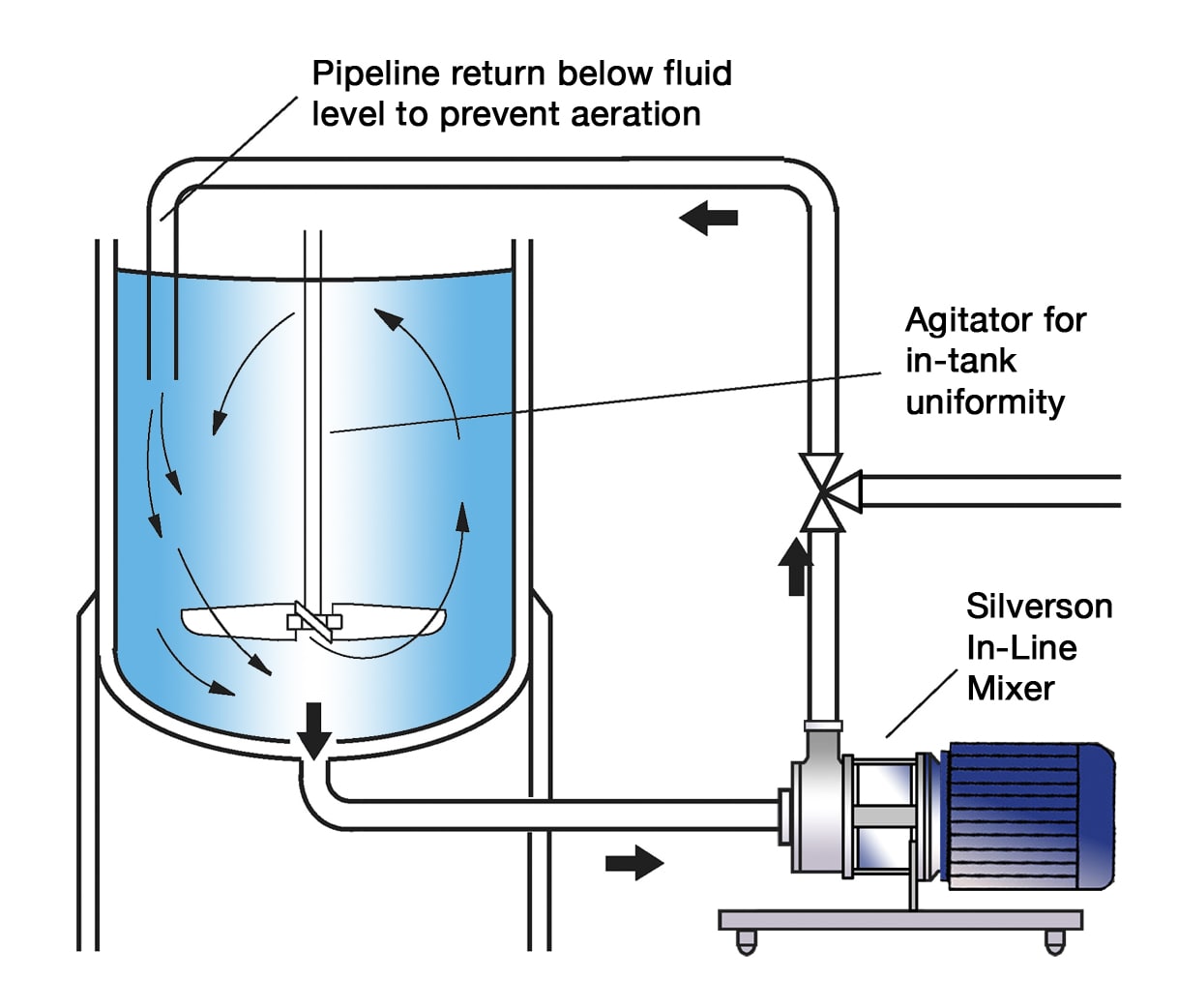

High Shear In-Line Mixers

- Ideal for larger batches

- Easily retrofitted to existing plant

- Must be used in conjunction with an efficient in-tank agitator to wet out powder

- Aeration free

- In-Line mixers will generally need to be pump fed when processing mustards

- Can be used to discharge vessel

- Ultra Sanitary models available

- High Viscosity models available

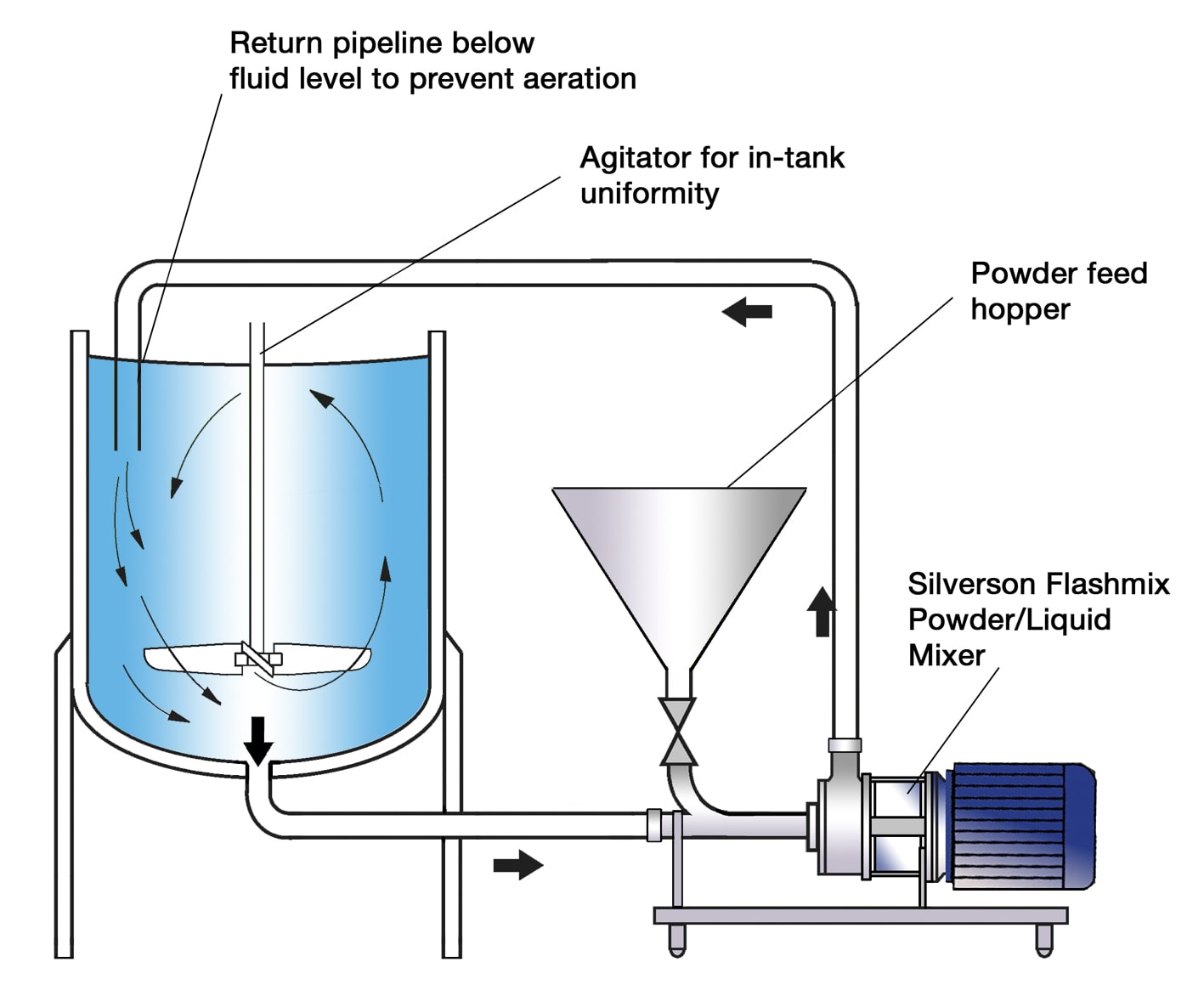

Silverson Flashmix

- Suitable for batches with large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Controlled powder addition rate

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required