Mixing with Honey

Honey is a natural, sweet, viscous food substance produced by honey bees that is amber or gold in color. It is a super-saturated glucose-fructose solution that is harvested in its raw liquid form and is used in a wide range of products in the food industry, where liquid honey is typically more desirable. Honey is also used in the cosmetic and pharmaceutical industries for its functional and medicinal properties as an antioxidant. However, it can be extremely difficult to process due to its viscous and ‘sticky’ characteristics. Silverson has proven capabilities with honey in the following food applications:

- Blending different grades of honey: Honey is a natural product and variations occur seasonally and by location. Different types/grades of honey can be blended to provide a uniform product.

- Dispersion of crystals resulting in clear/runny honey: Crystallized honey requires heating and holding at temperature to remove “seeds” and return honey to liquid form.

- Addition of other products to honey to make flavored products, i.e., additional powders such as flavorings.

- Honey as an ingredient, e.g. cereal coatings, nut/granola bars, blending with oil (to coat roasted vegetables), honey roasted peanut coatings.

The Problem

When manufacturing honey-based products, a number of problems can arise:

- Processing crystallized honey requires heating and holding the product at temperature, this destroys the seeds and reduces the viscosity of the honey, but super-heating honey is not desirable as it can lead to changes in flavor and remove functional properties.

- Some designs of conventional agitators and mixers are not able to process higher viscosity products such as honey and as a result localized mixing occurs. This is where the mixer is not able to generate enough movement to keep the entire contents of the vessel in motion and therefore, only the product that is local to the mixer is turned over.

- Introduction of powders and other flavors into honey is difficult, especially low-density powders as these tend to ‘raft’ on the surface.

- Aeration must be minimized as entrained air is very difficult to remove. This causes clouding and color change in the honey.

- Long process times are often required to ensure a uniform dispersion.

- When using conventional mixing equipment to blend liquid of different viscosities stratification can occur, particularly where there is a wide difference in the viscosity of the phases, such as honey and water mixes. This leads to long mixing times, poor consistency and variation from batch to batch.

The Solution

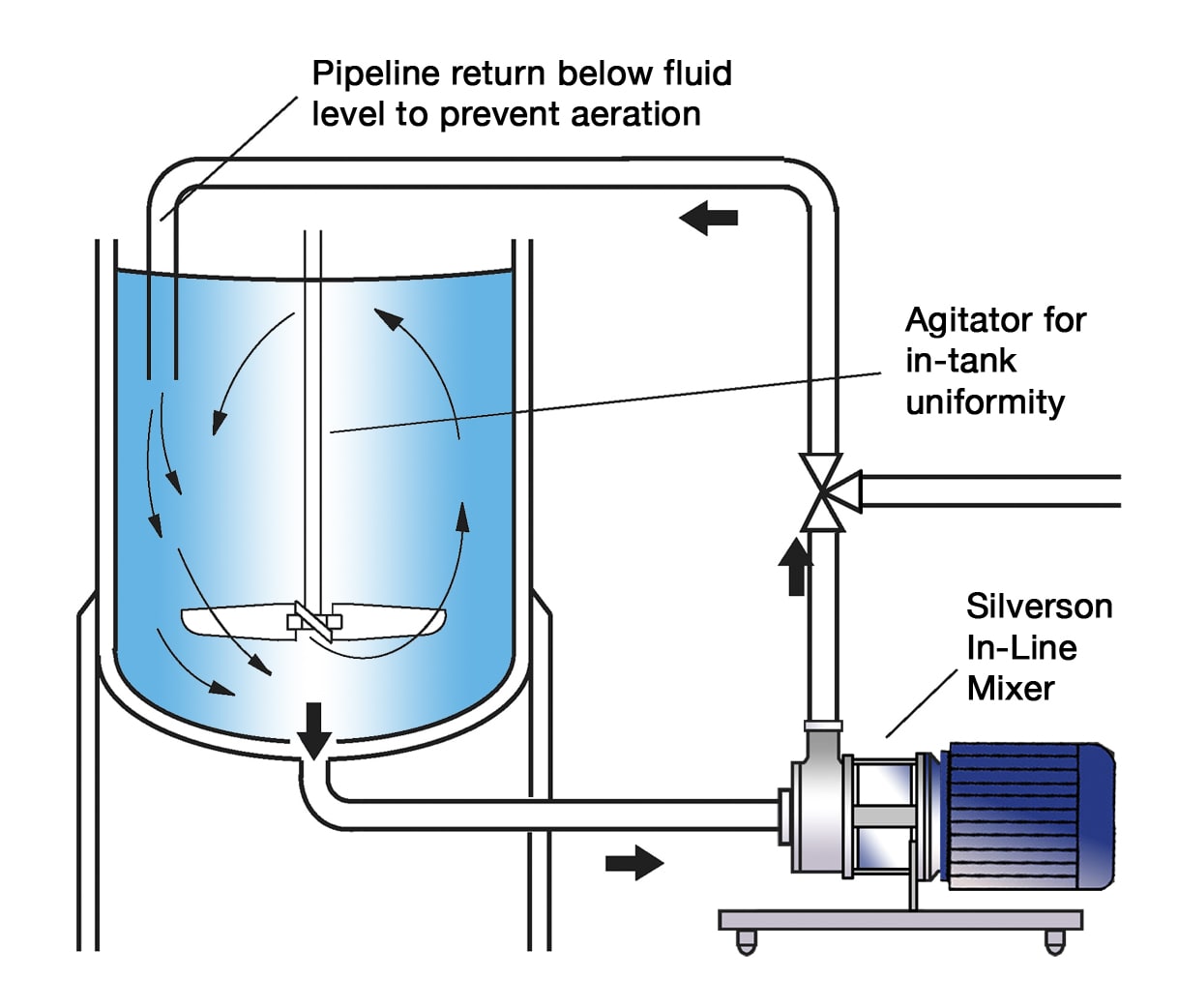

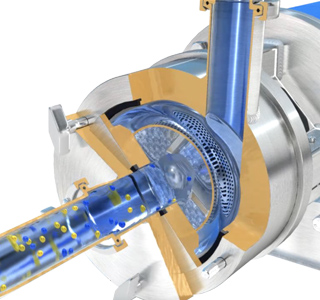

A Silverson In-Line mixer is ideal for blending different grades of honey. The In-Line mixer can also be used for mixtures of honey with other liquids and to decrystallize honey. Operation is as follows:

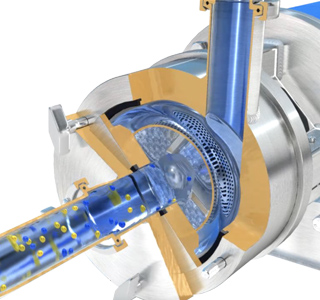

Stage 1

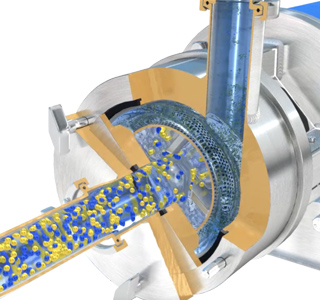

The vessel is gravity fed with honey and any other liquid/powdered ingredients are added. The mixer is started and the high-speed rotation of the In-Line mixer’s rotor blades creates a powerful suction which draws the liquids and any powdered ingredients into the high shear zone of the workhead.

Stage 2

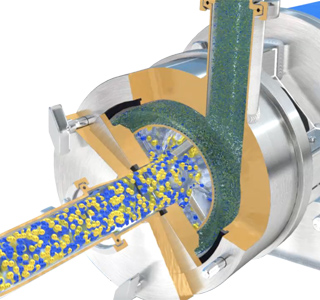

The materials are subjected to intense shear in the confined area of the workhead. Liquids are blended instantaneously. Any powder agglomerates which may have formed are broken down in the gap between the rotor blades and stator wall, exposing an increasing surface area to the surrounding liquid.

Stage 3

The materials are forced out of the stator and returned to the vessel by the self-pumping In-Line mixer. Fresh material is simultaneously drawn into the workhead developing circulatory mixing cycle, accelerating the hydration process and eliminating localized mixing. The whole mixing process is completely aeration-free as the mixer, pipework and vessel form a closed system.

-

Stage 1

Stage 1

The vessel is gravity fed with honey and any other liquid/powdered ingredients are added. The mixer is started and the high-speed rotation of the In-Line mixer’s rotor blades creates a powerful suction which draws the liquids and any powdered ingredients into the high shear zone of the workhead.

-

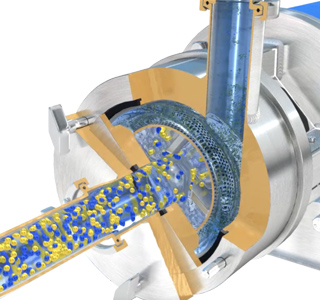

Stage 2

Stage 2

The materials are subjected to intense shear in the confined area of the workhead. Liquids are blended instantaneously. Any powder agglomerates which may have formed are broken down in the gap between the rotor blades and stator wall, exposing an increasing surface area to the surrounding liquid.

-

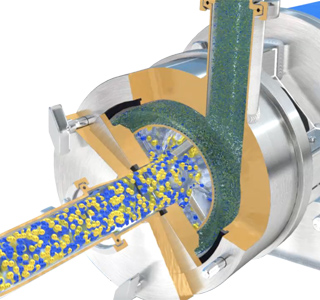

Stage 3

Stage 3

The materials are forced out of the stator and returned to the vessel by the self-pumping In-Line mixer. Fresh material is simultaneously drawn into the workhead developing circulatory mixing cycle, accelerating the hydration process and eliminating localized mixing. The whole mixing process is completely aeration-free as the mixer, pipework and vessel form a closed system.

The Advantages

The use of a Silverson mixer for work with honey has a number of advantages:

- Silverson mixers are able to blend liquids of widely varying viscosity and achieve a uniform blend, eliminating the stratification problems that may occur with an agitator.

- Mixing operations can be carried out in a closed system, eliminating aeration.

- The positive mixing of a Silverson mixer ensures that all ingredients are uniformly dispersed throughout the product.

- The self-pumping action of a Silverson In-Line mixer can handle higher viscosity formulations and recirculate the product back to the vessel without additional pumping equipment being required.

- Improved batch-to-batch consistency.

- Fast processing times reduces the risk of unintentional temperature rise caused by long mixing times.

- High Shear Batch mixers ensure rapid incorporation and dispersion of any powdered ingredients eliminating problems with rafting, and forms an agglomerate-free solution.

Silverson has a range of mixers suitable for honey applications, the selection of which is dependant on the application, ingredient type, batch size and position of the mixer within the mixing vessel. The Silverson trial program allows customers to test their application at Silverson's purpose-built testing center to find the most suitable mixer for their product.

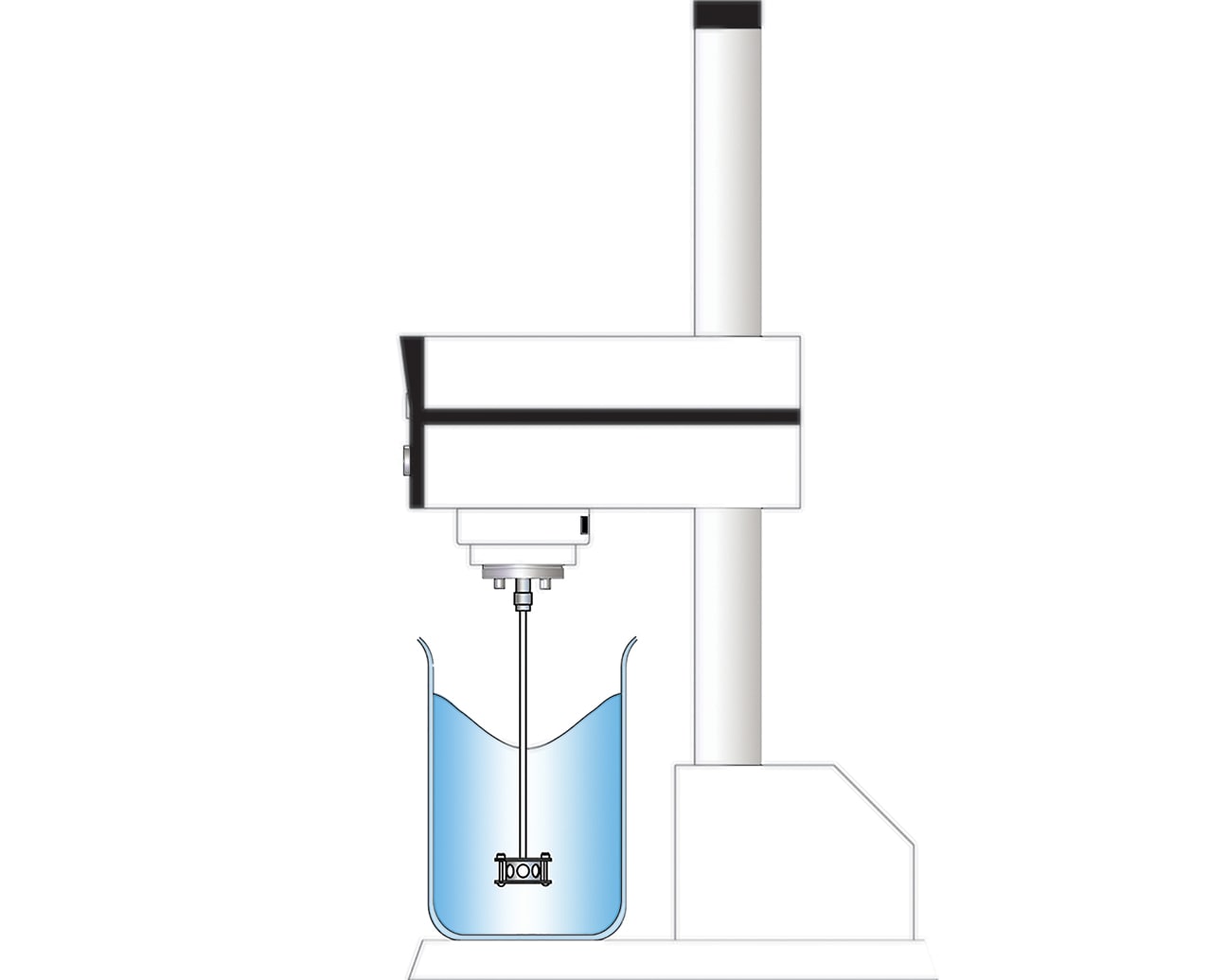

Silverson Laboratory Mixers

- Ideal for laboratory scale and R&D work

- Able to disperse low-density powders such as bee pollen, Ginseng powder and fresh royal jelly

- Can accurately predict the performance of production scale mixers

- A High Viscosity In-Line mixer, a Powder/Liquid mixer and Ultramix assembly all available at Laboratory scale and built to the same fine tolerances as production scale units

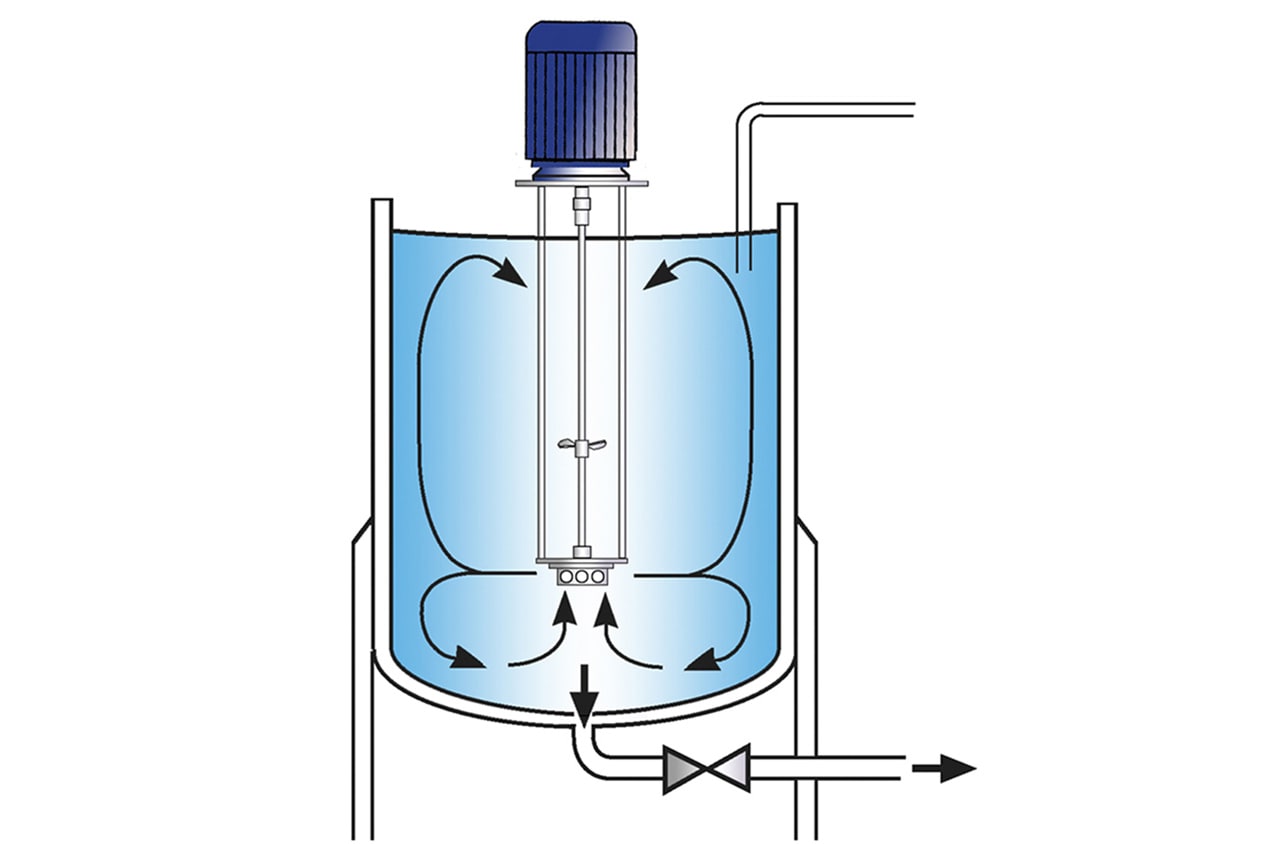

High Shear Batch Mixers

- Ideal for blending different grades of honey and the manufacture of honey-based coatings and sauces

- Can also be used for honey/water mixes and decrystallizing honey

- Can be used in conjunction with an anchor stirrer/scraper for higher viscosity mixes to help maintain movement in the vessel

- Small units available for R&D and pilot production

High Shear In-Line Mixers

- Ideal for blending different grades of honey and the manufacture of honey-based coatings and sauces

- Can also be used for honey/water mixes and decrystallizing honey

- Completely aeration-free processing as the mixer, pipework and vessel form a closed system

- Self-pumping High Viscosity models available, eliminating the need for additional feed pumps

- Easily retrofitted to existing process

- Ultra Sanitary units available

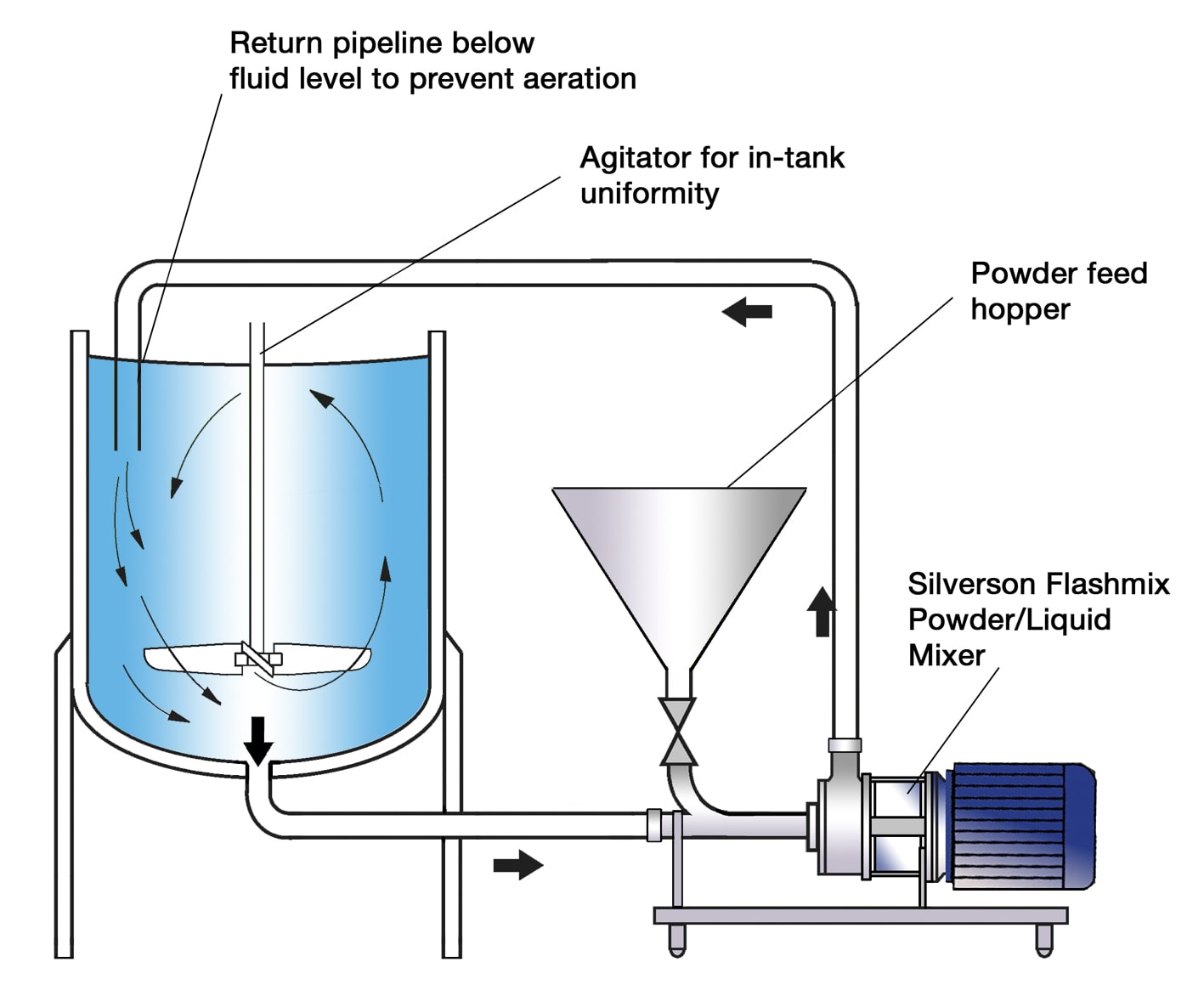

Silverson Flashmix

- Ideal for larger batches

- Suitable for dispersion of powders such as cocoa for the manufacture of flavored honey products and spreads

- Minimized aeration

- Minimized cleaning requirements

- Suitable for higher viscosity mixes

- Controlled powder addition rate

- Additional hopper types are available to assist with flow of more cohesive powders