Manufacture of Toothpaste

Toothpastes are generally either white abrasive pastes or clear gels. Although the formulations differ, they share many common ingredients; these may vary from country to country according to legislation on use of ingredients, etc.

The Process

Typical ingredients and their function are shown in the table:

Ingredient type |

Typical % |

Function |

|---|---|---|

| Liquid Base | White: 30 Gel: Up to 80 |

Polyols, most commonly sorbitol (glycerin is also used) act as a humectant, preventing the product from drying out and preserving the texture and flavor. Polyol solutions can contain up to 30% water; additional water (10 - 25%) completes the liquid base. |

| Fillers and Abrasives | White: 20 - 50 Gel: 15 - 25 |

Various ingredients provide the polishing action in white toothpastes; these include calcium carbonate, hydrated silica, sodium bicarbonate, dicalcium phosphate and sodium metaphosphate. In clear gel type products, hydrated silica is used to provide polishing and “body.” |

| Rheology Modifiers | 0.5 - 2 | Used to obtain several properties: the toothpaste must flow easily but not too rapidly from the tube; it must “break” easily without being “stringy”; it must sit on the toothbrush without sinking in; these ingredients are also used to keep fillers/abrasives in suspension. Various ingredients are used, including CMC, carrageenan, xanthan gum and cellulose gum. |

| Detergent | 0.5 - 2.5 | Added to make the product foam when brushing. This helps dispersion and retention of the product in the mouth. SLS (Sodium Lauryl Sulphate) is most commonly used. |

| Active Ingredient | 0.3 | Fluoride can be added to help prevent tooth decay. Sodium fluoride, sodium monofluorophosphate and stannous fluoride are used, subject to legislation, etc. |

| Flavor | 0.5 - 2 | Flavoring is added to disguise the unpleasant taste of the detergent. It also provides “freshness.” Typically mint (and sometimes menthol and cinnamon) flavoring oils are used. |

| Sweetener | 0.2 | Sweeteners include sodium saccharinate. |

| Coloring | 0.1 | Titanium dioxide can be added to white toothpaste as a coloring; gel toothpastes may be manufactured in a number of colors using food grade products. |

| Preservative | 0.2 | Sodium benzoate, ethyl paraben, methyl paraben. |

Processing methods vary depending on the product type and ingredients used. A typical process could be described as follows:

- The liquid base is prepared first - water, sorbitol/glycerin and other liquid ingredients.

- Rheology modifiers may be pre-mixed with a non-aqueous liquid ingredient such as glycerin or the flavoring oil, or dry blended with other powdered ingredients to aid dispersion.

- The active ingredient, sweetener and preservative are added and dispersed.

- The abrasive/filler is then added. This may be supplied as a slurry, or premixed with part of the water prior to blending with the liquid base.

- Flavoring and coloring are added.

- The detergent is added last under slow speed agitation to minimize foaming. It is typically in solid form to avoid adding water to the formulation at this stage.

The Problem

Aeration is a major problem in toothpaste manufacture. All powders contain a certain amount of air, and the detergent can exacerbate the problem. Mixing is usually carried out under vacuum to overcome this. Other problems which can be encountered include:

- Rheology modifiers tend to form lumps which are difficult to break down by agitation. Premixing with other liquid or powdered ingredients increases process time and costs.

- Some rheology modifiers require high shear in order to obtain functionality.

- Some ingredients, e.g. hydrated silica have a low density and are very difficult to incorporate and wet out.

- Conventional agitators tend to cause aeration, especially when incorporating powders.

- Abrasives such as calcium carbonate can be supplied as a slurry. These may require deagglomeration.

The Solution

Manufacturing of gel toothpastes can be carried out using a Silverson High Shear Mixer, however the high viscosity and abrasive nature of white toothpastes means that mixing with a high speed rotor/stator is not appropriate for some aspects of the process, but significant advantages can be obtained in other stages of production, including:

- Preparation of the liquid base prior to the addition of the fillers and abrasive ingredients.

- Deagglomerating the mix before the detergent and thickeners are added, especially where fillers such as calcium carbonate are supplied as a slurry.

- “Refining” of finished product prior to packing. This would be carried out using a specially modified In-Line unit. We offer mixers capable of handling higher viscosities but a non-reciprocating positive displacement pump may be required for some products.

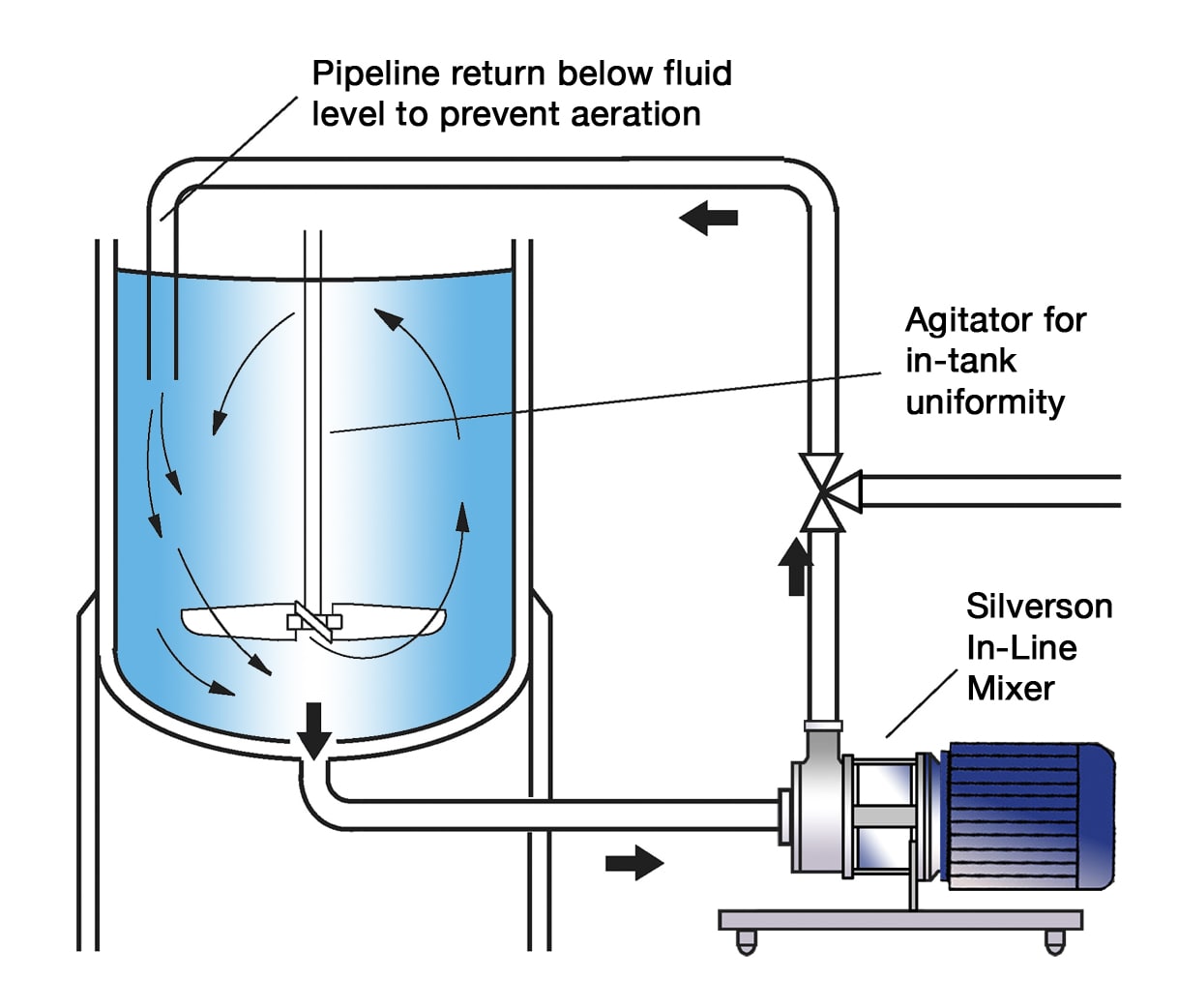

Typically an In-Line mixer would be used, which operates as illustrated below:

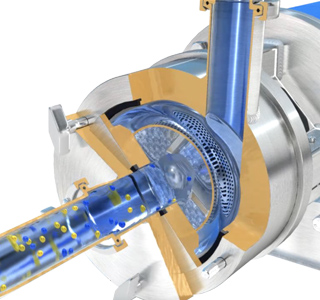

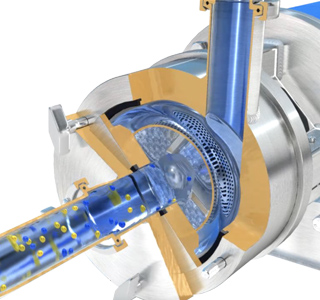

Stage 1

The high speed rotation of the rotor creates a powerful suction which draws the liquid and solids into the rotor/stator assembly.

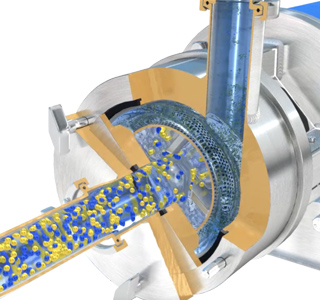

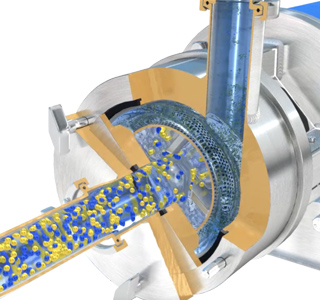

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are subjected to a milling action in the gap between the rotor and stator.

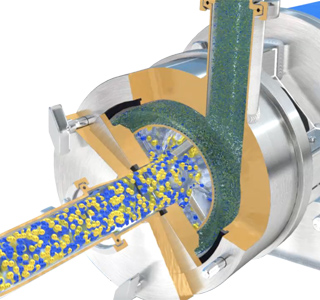

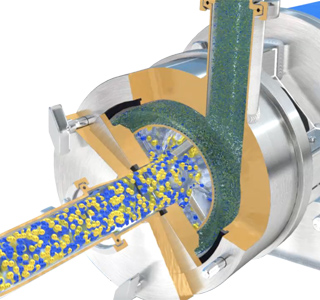

Stage 3

The product is then forced out through the stator as fresh material is drawn in. The continuous intake and expulsion of materials ensures the ingredients are deagglomerated and rapidly dispersed and/or hydrated.

-

Stage 1

Stage 1

The high speed rotation of the rotor creates a powerful suction which draws the liquid and solids into the rotor/stator assembly.

-

Stage 2

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are subjected to a milling action in the gap between the rotor and stator.

-

Stage 3

Stage 3

The product is then forced out through the stator as fresh material is drawn in. The continuous intake and expulsion of materials ensures the ingredients are deagglomerated and rapidly dispersed and/or hydrated.

The Advantages

- Processing time is dramatically reduced.

- Rapid incorporation and wetting out of powders.

- Greatly improved product quality, consistency and stability.

- Minimized aeration; certain units can be supplied for operation under vacuum.

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to existing process

- Self-pumping

- Can be used to discharge vessel

- Multistage units available

- Ultra Sanitary models available

- Mixers suitable for high viscosity products available