Manufacture of Smoothies

A smoothie is made by blending raw fruits or vegetables with water, fruit juice or milk. It may also contain other ingredients such as grains, herbs or proteins.

Generally a smoothie has a higher viscosity than a juice, due to the high solids content and the natural thickening effect of some ingredients, such as banana and mango.

The Process

Smoothies are produced in a wide range of batch sizes, from individual portions in catering establishments to bulk production.

Some manufacturers use whole fruit and/or vegetables while others may buy preprepared purées and blend them. Consequently there are many different methods used to produce smoothies and many different types of equipment are used. However the processing requirements are largely the same:

- Where smoothies are produced from purées and juices, the mixing system must be able to blend liquids of widely varying viscosities.

- When working with whole fruit and/or vegetables, a range of equipment may be required to chop and purée the solid ingredients, particularly if frozen solids, hard or fibrous raw materials are being used.

- The mixing system must be capable of dispersing any powdered ingredients such as milk powders and other nutritional supplements.

- After the initial disintegration stage further processing may be required to obtain the required smooth consistency and mouthfeel.

The Problem

The manufacturing process is subject to a number of problems:

- The small scale blending equipment widely used for this process has no production equivalent. Replicating the results from the laboratory or pilot production can therefore be very problematic on scaling up.

- Repeatability between batches is difficult to obtain.

- Poor processing can lead to unsatisfactory texture and mouthfeel.

- Conventional agitators cannot readily blend liquids of widely differing viscosities. Long mixing times may be required to achieve a uniform blend.

- Powdered ingredients can be difficult to incorporate and disperse, especially if added to higher viscosity smoothies.

The Solution

These problems can be overcome using a Silverson High Shear mixer. The high shear action of the rotor/stator workhead can rapidly disintegrate and pulp fruit and vegetables of all shapes and sizes, including hard solids. Operation is as follows:

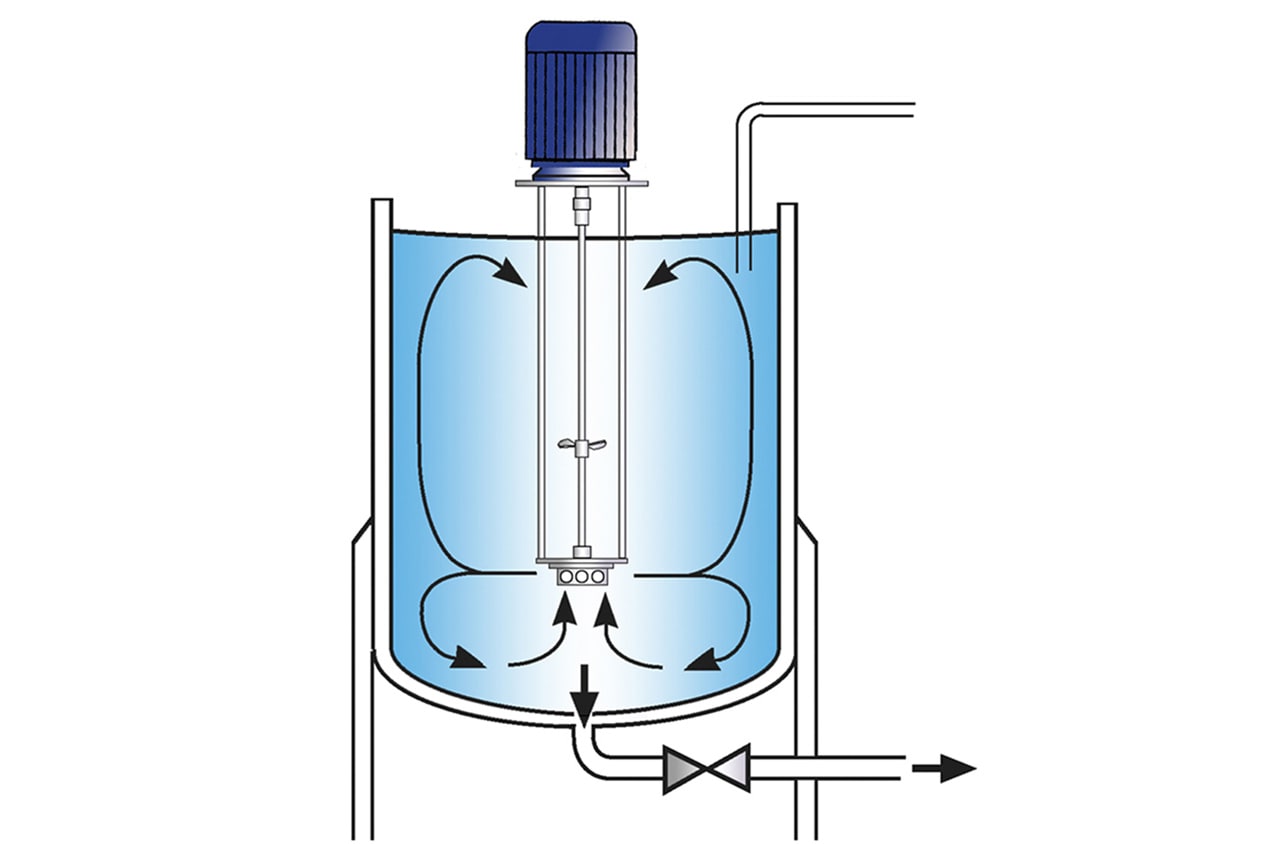

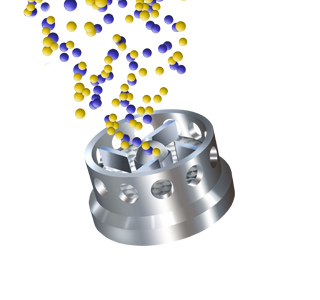

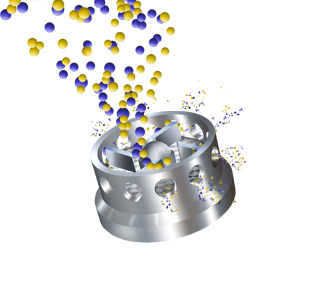

Stage 1

The vessel is charged with liquid and the mixer is started. The fruit and/or vegetables are added to the vessel and drawn into the rotor/stator workhead where they are rapidly disintegrated.

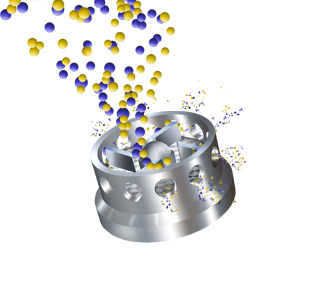

Stage 2

Centrifugal force drives the materials towards the periphery of the workhead, where they are subjected to intense high shear in the gap between the rotor and stator wall. The product is forced out of the stator and projected radially back into the body of the mix.

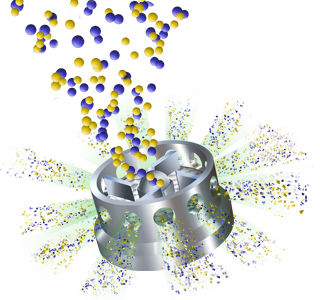

Stage 3

Fresh materials are simultaneously drawn into the workhead. In a short mixing cycle all the material passes many times through the workhead, producing a smooth, uniform mixture.

-

Stage 1

Stage 1

The vessel is charged with liquid and the mixer is started. The fruit and/or vegetables are added to the vessel and drawn into the rotor/stator workhead where they are rapidly disintegrated.

-

Stage 2

Stage 2

Centrifugal force drives the materials towards the periphery of the workhead, where they are subjected to intense high shear in the gap between the rotor and stator wall. The product is forced out of the stator and projected radially back into the body of the mix.

-

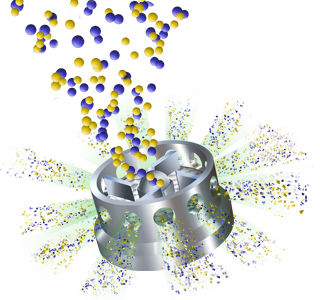

Stage 3

Stage 3

Fresh materials are simultaneously drawn into the workhead. In a short mixing cycle all the material passes many times through the workhead, producing a smooth, uniform mixture.

The Advantages

- Rapid disintegration and pulping of solids and incorporation of any powdered ingredients.

- Capable of blending liquids of widely differing viscosities.

- Interchangeable workheads available from coarse disintegrating heads to ultra-fine screens, allowing the user to obtain the desired consistency.

- Consistent, repeatable results.

- Scalable results across the entire Silverson product range.

The batch size, formulation, type of ingredients and the viscosity of the end product dictates which Silverson model is best suited to processing requirements:

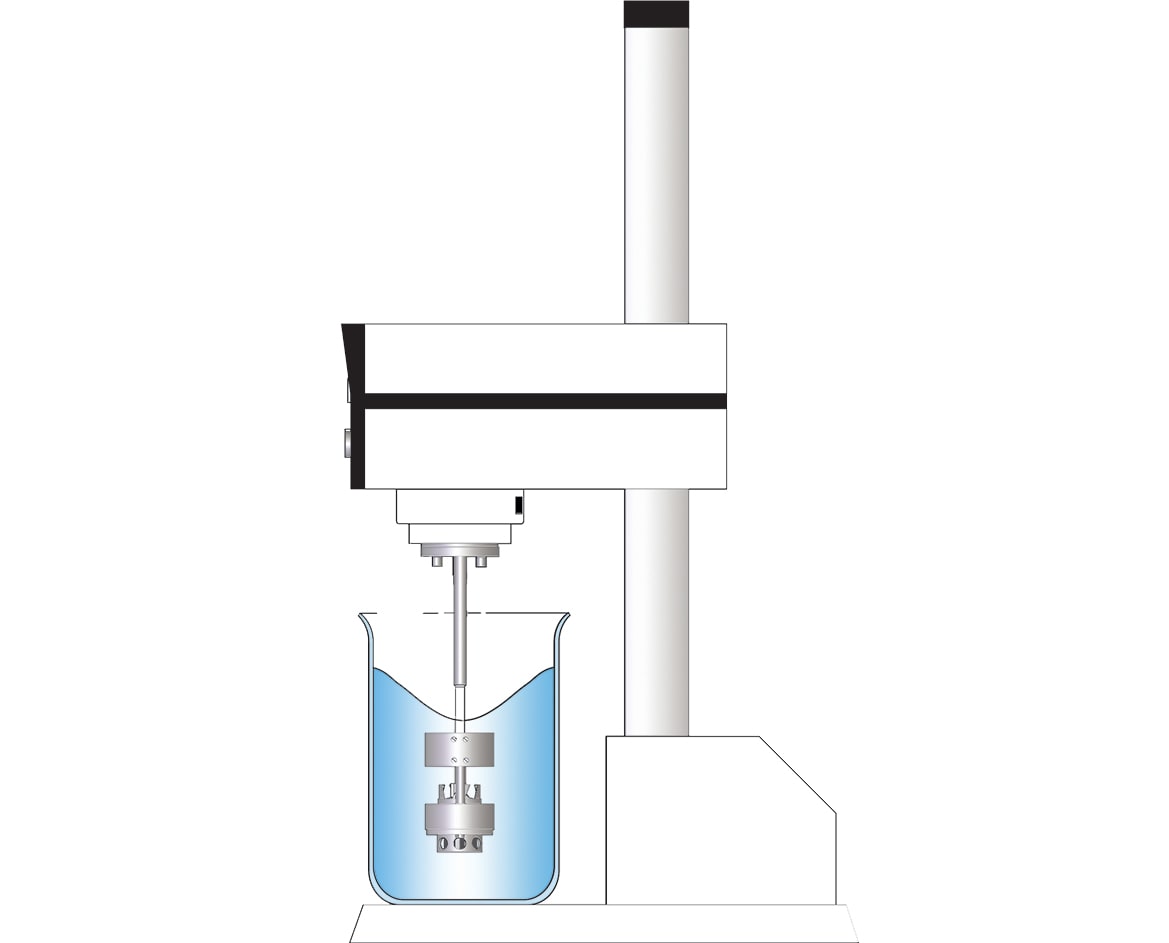

High Shear Laboratory Mixers

- Built to the same tolerances as production models, providing an easy and accurate means of scaling up

- Duplex assembly available for disintegration of solids

High Shear Batch Mixers

- Suitable for batches up to 300 US gallons

- Can be used on mobile floor stands

- Duplex mixers available for disintegrating larger solids

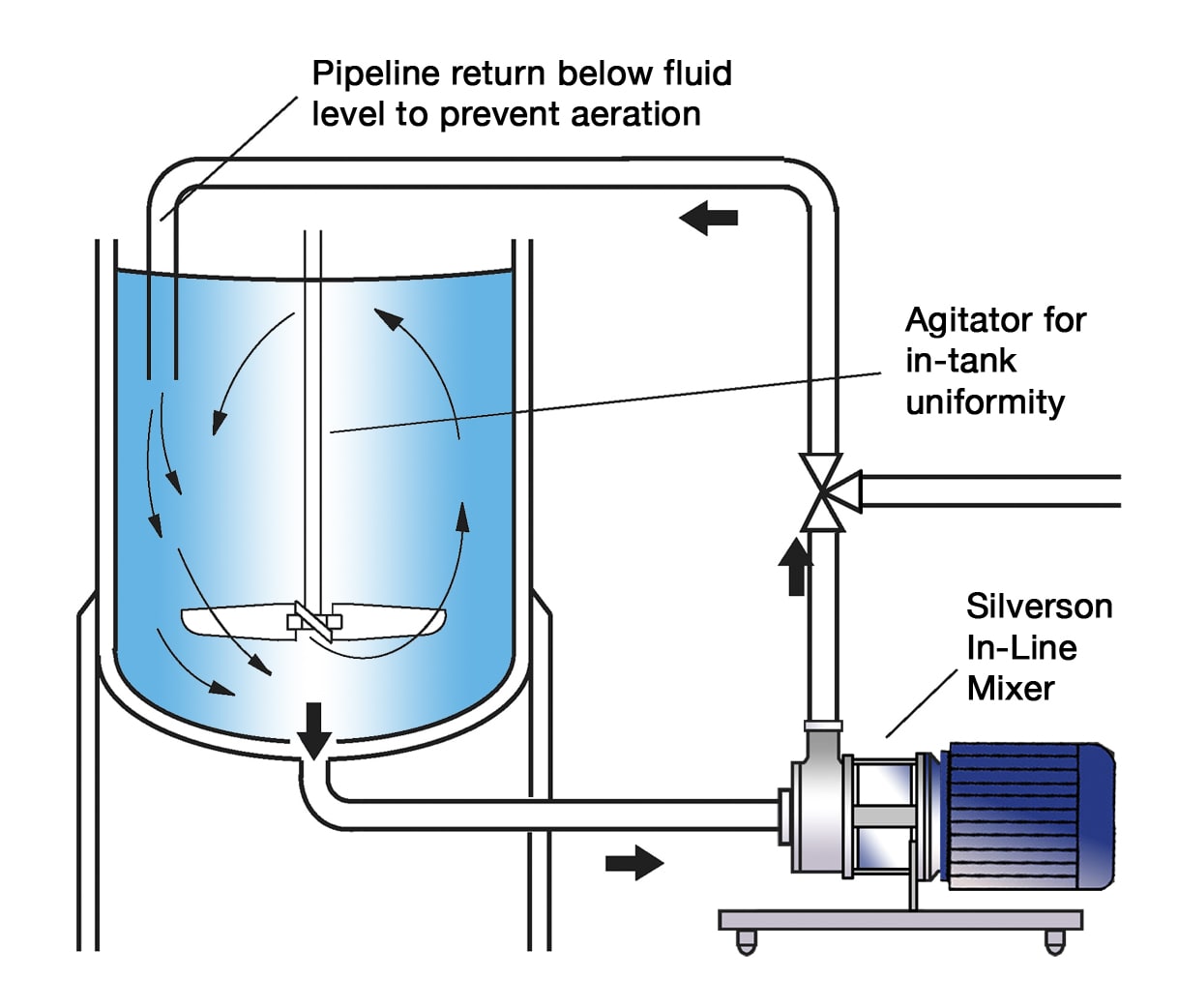

High Shear In-Line Mixers

- Ideal for larger batches

- Suitable for blending of purées via a manifold just prior to the inlet

- Provides finished smooth consistency to the product

- Easily retrofitted to existing plant

- Self-pumping

- Aeration free

- High Viscosity models available

- Designed for Cleaning-In-Place

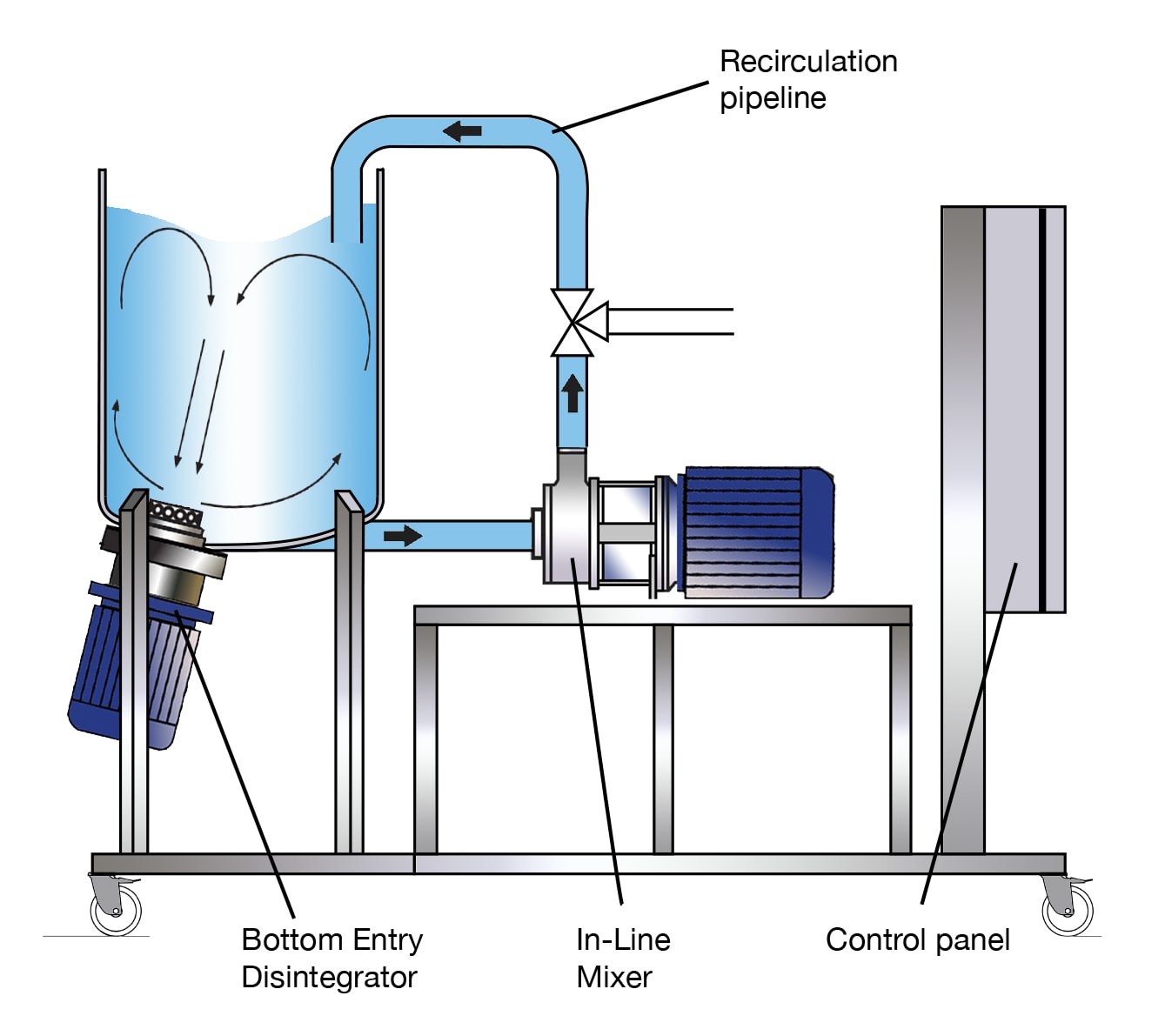

Silverson Blending Plant

- A complete system capable of disintegrating large solids without pre-treatment

- The Bottom Entry mixer provides the initial disintegration of the solids

- The In-Line mixer further refines the product to give the required smooth consistency