Dispersion of Starch

Starch is used as a thickening, stabilizing and binding agent in many foods, including soups, sauces, gravies and baked products. “Native” or unmodified starch is obtained from a variety of sources, including corn, tapioca, potato and rice, etc. Unmodified starches are relatively easy to disperse and generally do not increase in viscosity until heated or cooked.

Starch can be modified by a number of methods to obtain functional properties such as texture, appearance, viscosity and stability under heating or freezing.

Pregelatinized starches are modified by precooking then drying so that they thicken when added to cold water - they are sometimes called CWS (cold water swelling) starches. These products can be difficult to disperse and hydrate.

The Process

Despite the diversity of end uses, and the various processing methods and equipment used, there are a number of common processing requirements which must be satisfied in order to successfully disperse starch:

- The powder/liquid mixing system must be capable of rapidly incorporating the starch powder and dispersing it throughout the contents of the mix.

- Vigorous in-tank movement must be maintained as viscosity rises.

- The powder must be reduced to the smallest possible particle size to maximize yield.

The Problem

The manufacturing process is subject to a number of problems:

- Agglomerates can easily form when the pregelatinized starch powder is added to water. Conventional agitators do not produce sufficient shear to break them down.

- Once viscosity increase has started, agitation of the solution and incorporation of powder becomes increasingly difficult.

- Long mixing times are required to complete dispersion/hydration.

- Potential full yield is difficult to obtain using traditional methods.

- Dry premixing of powdered ingredients increases labor costs and process time.

- Undissolved starch can gradually hydrate during storage or subsequent processing, leading to undesired changes in product viscosity.

The Solution

These problems can be overcome using a Silverson High Shear mixer. Operation is as follows:

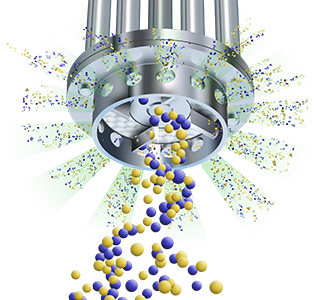

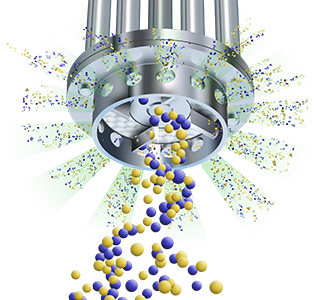

Stage 1

The vessel is charged with liquid and the mixer is started. The starch is added to the water as rapidly as the mixer will take it in. The high speed rotation of the rotor blades creates a powerful suction which draws the liquid and powder into the workhead where they are rapidly mixed.

Stage 2

Centrifugal force drives the powder and liquid towards the periphery of the workhead, where they are subjected to intense high shear in the gap between the rotor and stator wall. The product is forced out of the stator and projected radially back into the body of the mix.

Stage 3

Fresh materials are simultaneously drawn into the workhead. In a short mixing cycle all the material passes many times through the workhead, progressively reducing the particle size and exposing an increasing surface area to the surrounding liquid, accelerating hydration.

-

Stage 1

Stage 1

The vessel is charged with liquid and the mixer is started. The starch is added to the water as rapidly as the mixer will take it in. The high speed rotation of the rotor blades creates a powerful suction which draws the liquid and powder into the workhead where they are rapidly mixed.

-

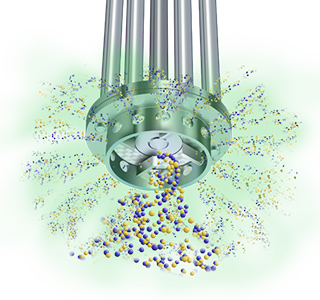

Stage 2

Stage 2

Centrifugal force drives the powder and liquid towards the periphery of the workhead, where they are subjected to intense high shear in the gap between the rotor and stator wall. The product is forced out of the stator and projected radially back into the body of the mix.

-

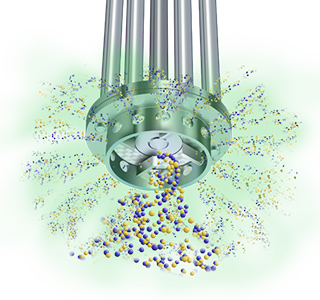

Stage 3

Stage 3

Fresh materials are simultaneously drawn into the workhead. In a short mixing cycle all the material passes many times through the workhead, progressively reducing the particle size and exposing an increasing surface area to the surrounding liquid, accelerating hydration.

The Advantages

- Operator error during powder addition is virtually eliminated.

- Powder can be incorporated despite the increase in viscosity.

- Agglomerate-free mix.

- Rapid mixing times.

- Maximized yield of thickening effect as starch is fully hydrated.

- Greater uniformity between batches.

The batch size, formulation, type of ingredients and the viscosity of the end product dictates which Silverson model is best suited to processing requirements:

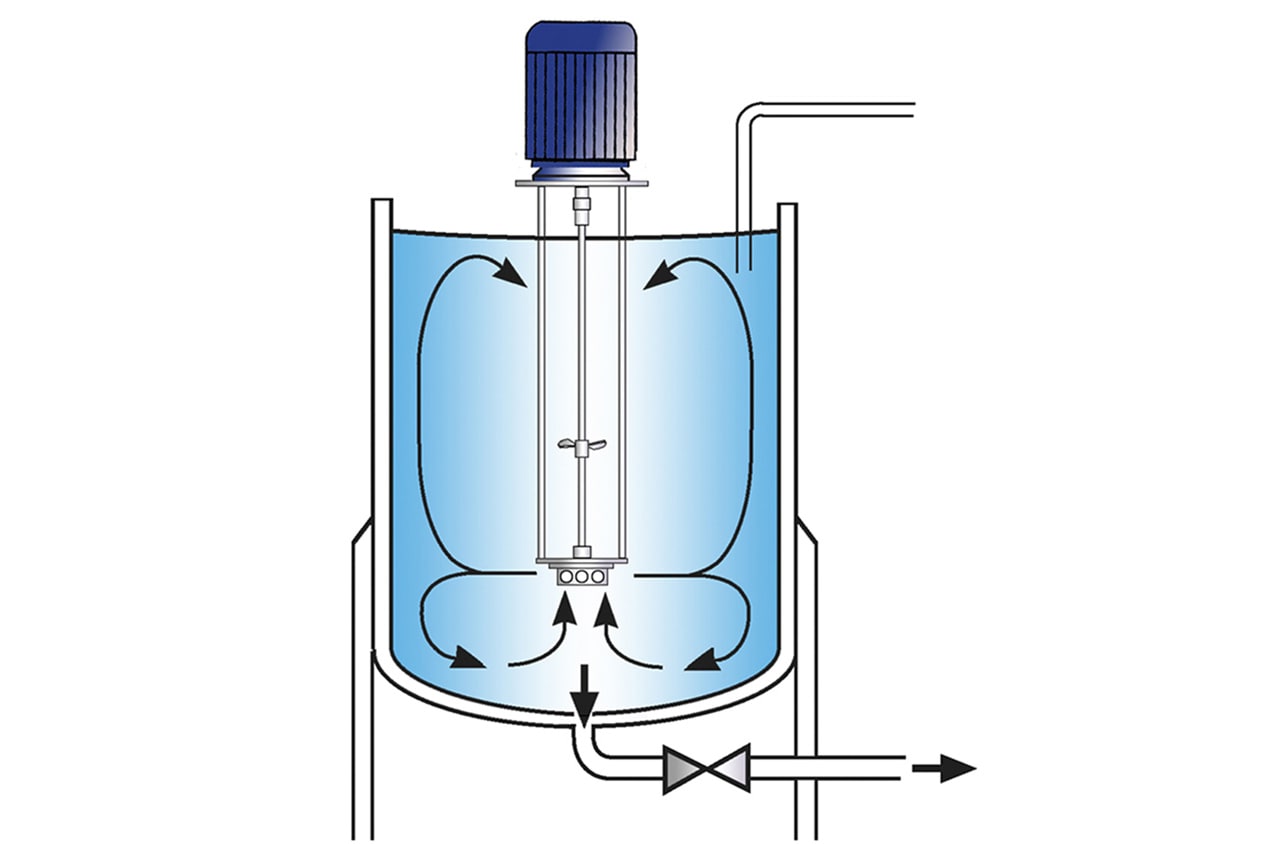

High Shear Batch Mixers

- Suitable for batches up to 300 US gallons

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

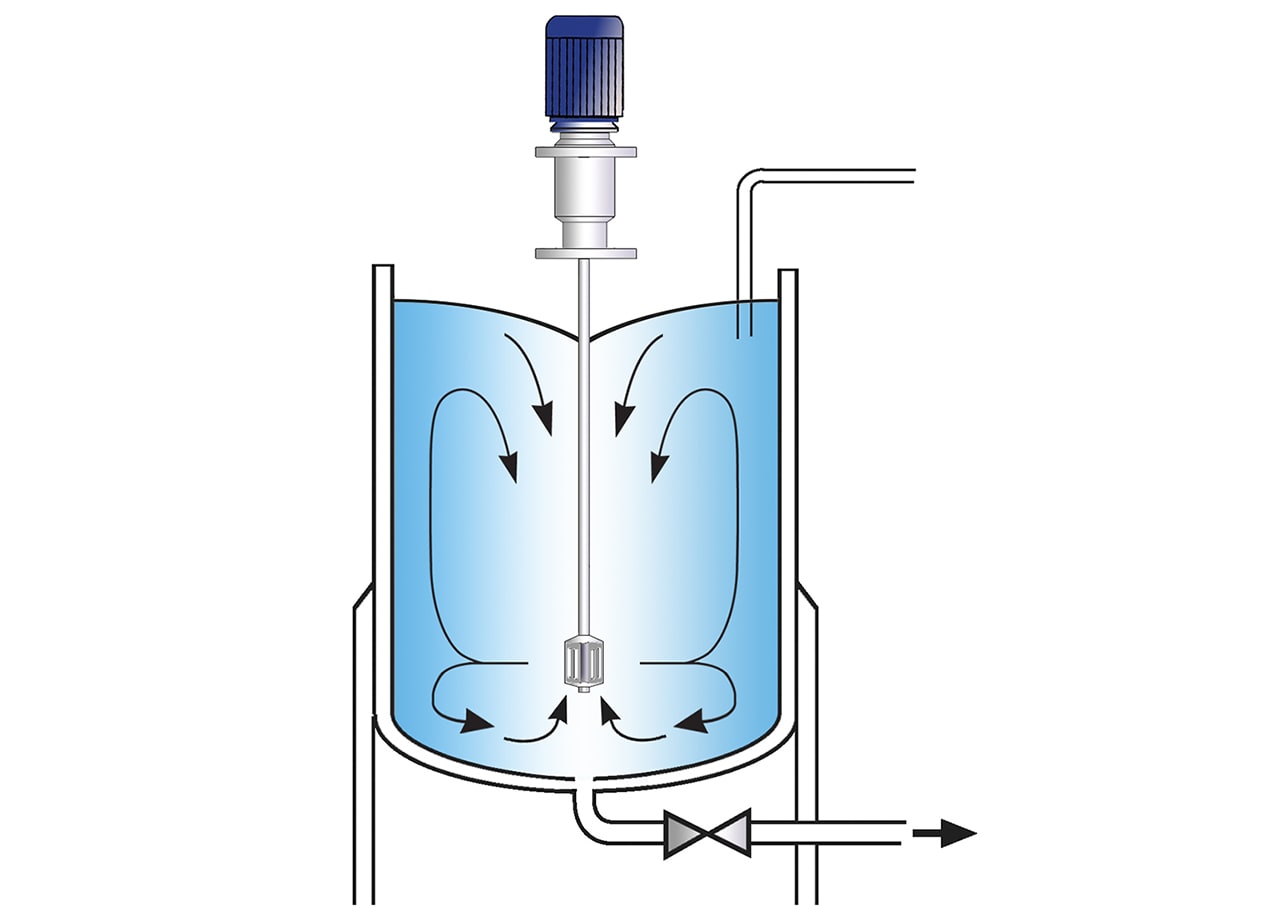

Silverson Ultramix

- Capable of rapidly incorporating large volumes of powders

- Suitable for higher viscosity mixes

- Single-piece dynamic mixing head designed for CIP

- Low maintenance

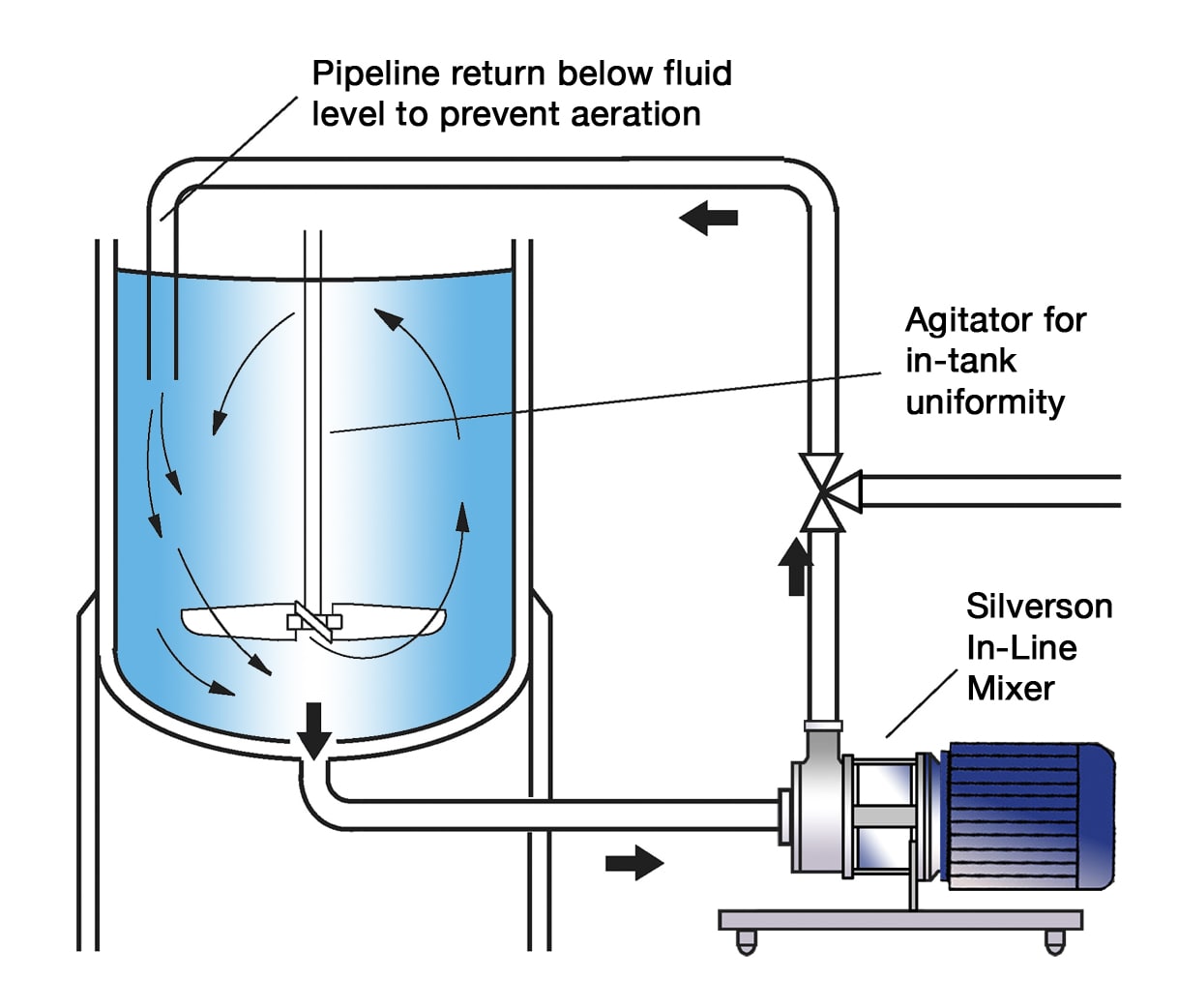

High Shear In-Line Mixers

- Ideal for larger batches

- Must be used in conjunction with an efficient in-tank agitator to wet out powder

- Easily retrofitted to existing plant

- Self-pumping

- Aeration free

- High Viscosity models available

- Designed to be Cleaned-In-Place

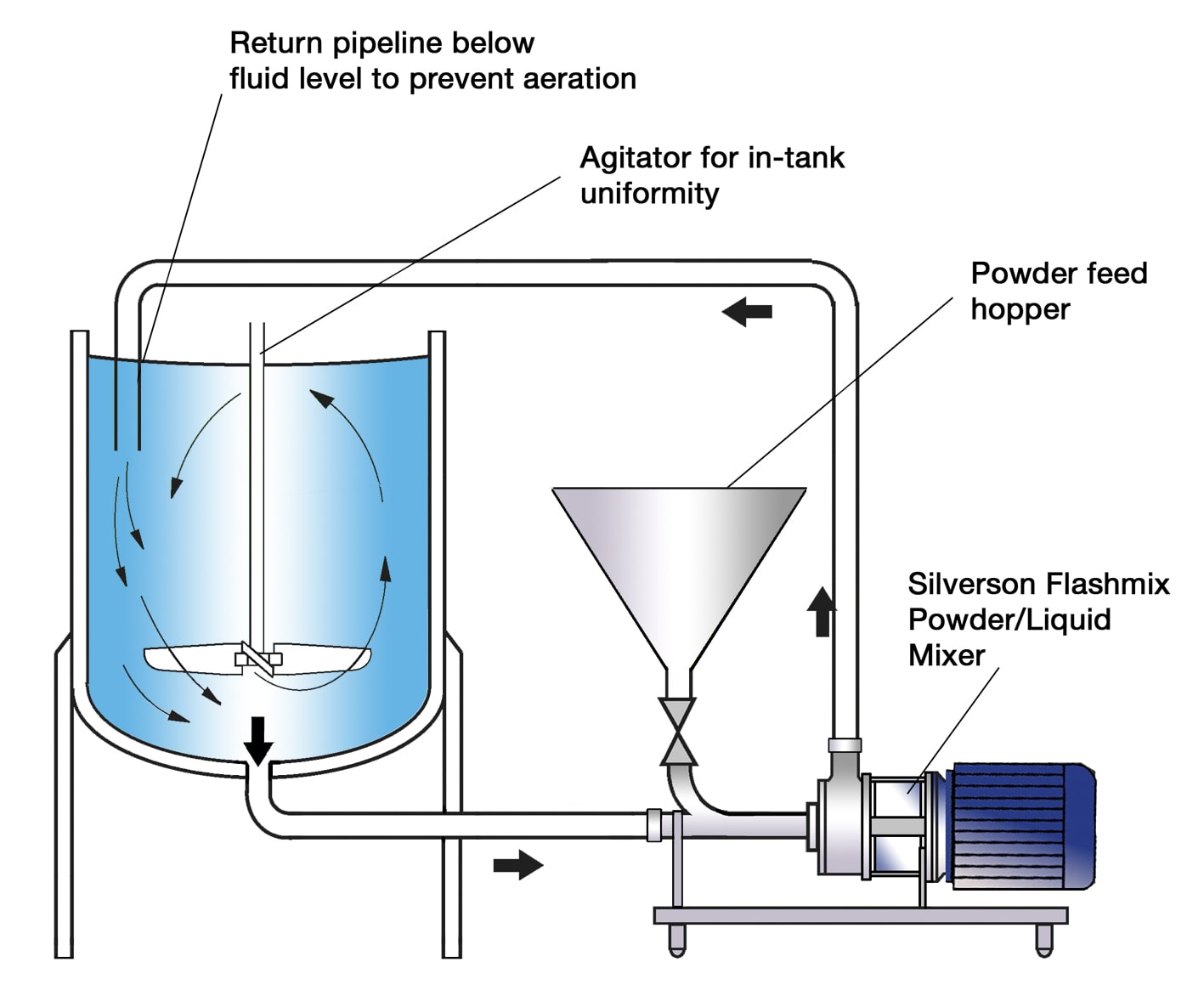

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Suitable for higher viscosity mixes

- Minimum operator input required