Dispersion and hydration of Alginates

Alginates are natural polymers (biopolymers) or hydrocolloids that are obtained from brown seaweed and are water-soluble when mixed under the correct conditions. Alginates are used as thickening, stabilizing and gelling agents in the food, pharmaceutical and chemical industries in products such as spreads, sauces and bakery products to provide the correct mouthfeel in low-fat formulations. Alginates have film-forming properties when mixed at high concentrations and dried, making them suitable for use in plant-based products such as vegetarian sausage casings/skins. They are also used in pharmaceutical applications, such as non-woven dressings where they are often combined with CMC.

The Process

Alginates are available in powdered and granular form, both of which have a strong tendency to form lumps when added to water and a number of dispersion and hydration methods are used to overcome this. Calcium interferes with the creation of the gel structure and therefore, alginates should be dispersed in deionized water in order to achieve full functionality. A typical dispersion process would be as follows:

- The process vessel is charged with water.

- The agitator or stirrer is started.

- The alginate is often premixed dry with another powdered ingredient such as salt or sugar, to separate the particles and allow for easier dispersion with simple stirrers.

- The alginate is carefully added into the vortex created by the agitator at a controlled rate to try and reduce the formation of agglomerates. This must be done as quickly as possible by the operator as powder incorporation becomes increasingly difficult as the viscosity of the mixture increases.

- Mixing is continued until the alginate has been fully dispersed and hydrated.

- A filtration step may be required to remove any agglomerates and/or unhydrated alginate.

The Problem

When dispersing alginates there are a number of problems that can arise during the mixing process:

- Agglomerates can easily form, even when the above steps are taken to reduce the risk. Agitators do not produce sufficient shear to rapidly break these down.

- Controlled powder addition into liquid can help reduce the formation of agglomerates but this method is impractical for large scale productions and can be exacerbated by operator error.

- Pre-mixing the alginate with other dry ingredients increases processing times.

- Potential full yield is difficult to obtain using traditional methods.

- Combining alginates with other gums, such as pectin, increases the viscosity dramatically which can lead to problems with localized mixing when the mixing equipment is unable to handle the viscosity increase and continue to move the product around the vessel.

- Aeration can cause problems, especially at higher concentrations where the viscosity of the mixture is higher. Entrained air in the mixture is very difficult to remove and causes clouding of clear gels.

The Solution

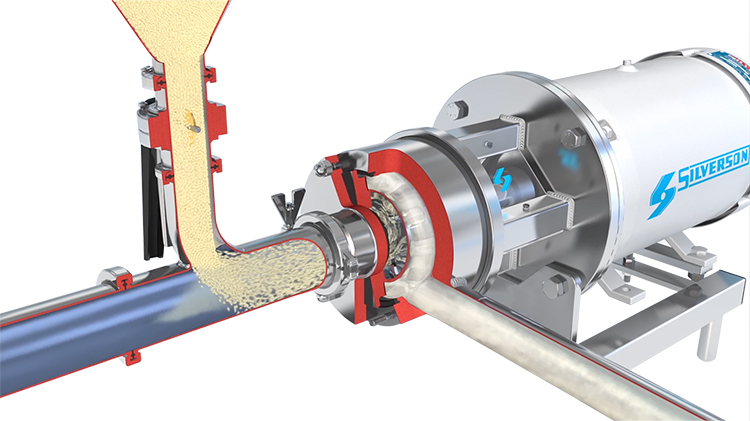

Silverson Machines’ high shear mixing technology effectively disperses alginates in a fraction of the time taken by conventional mixers and agitators. Here’s how it works:

Stage 1

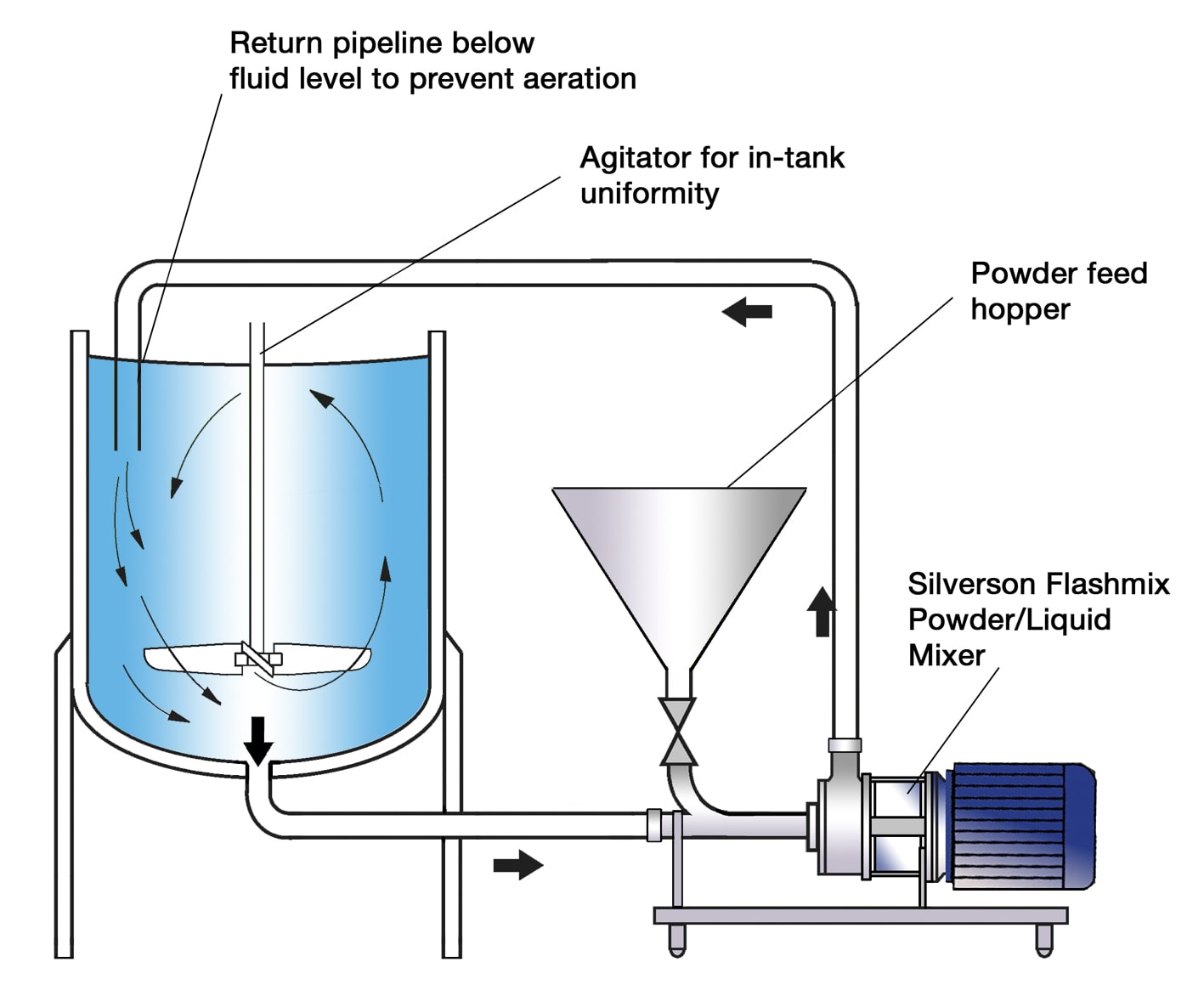

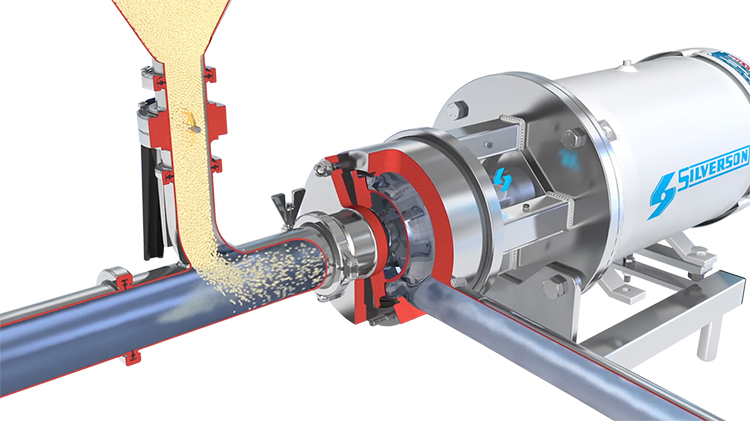

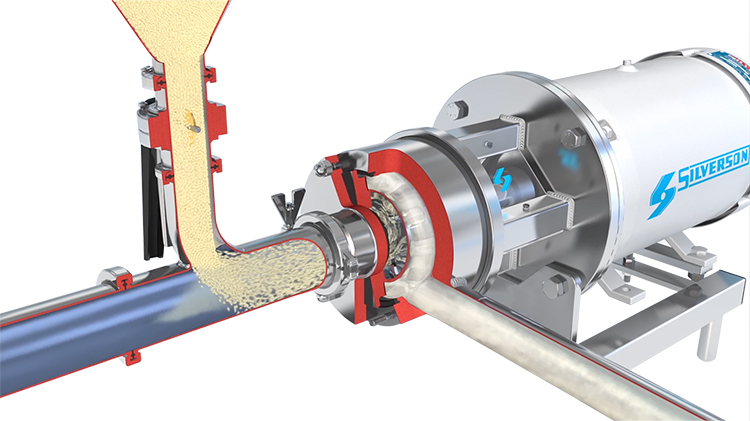

The vessel is charged with deionized water and recirculation through the Flashmix is started. The alginate is added to the powder feed hopper and when the valve is opened it is drawn directly into the high-velocity liquid stream.

Stage 2

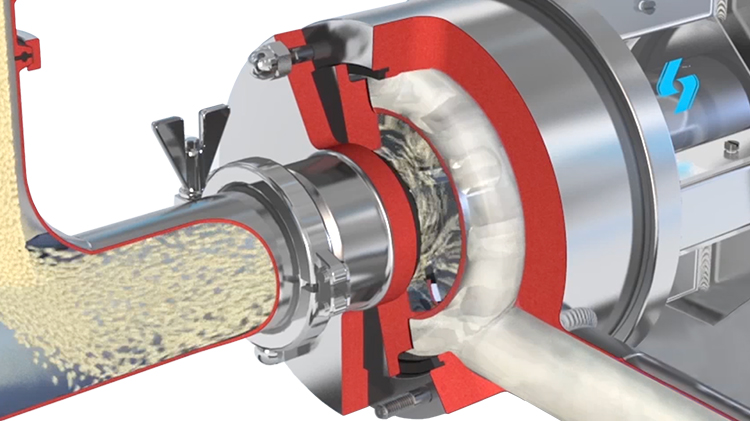

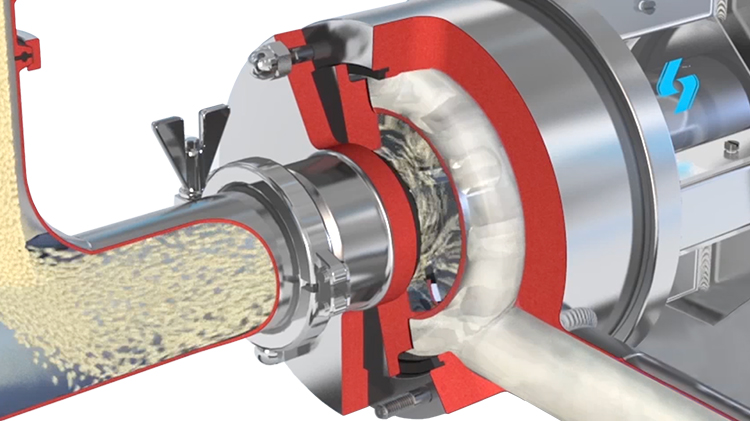

The powder/liquid mix passes immediately into the rotor stator workhead and is subjected to intense mechanical and hydraulic shear. This ensures that it is completely dispersed and agglomerate-free.

Stage 3

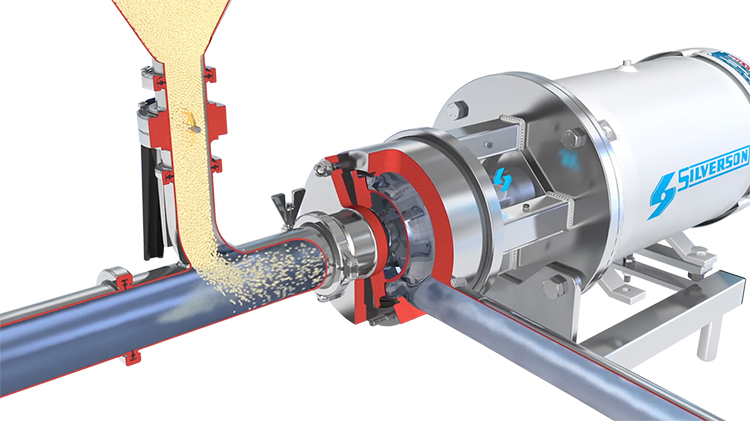

The product is pumped back to the process vessel by the self-pumping action of the machine. Once powder addition is complete, a short period of recirculation completes the process.

-

Stage 1

Stage 1

The vessel is charged with deionized water and recirculation through the Flashmix is started. The alginate is added to the powder feed hopper and when the valve is opened it is drawn directly into the high-velocity liquid stream.

-

Stage 2

Stage 2

The powder/liquid mix passes immediately into the rotor stator workhead and is subjected to intense mechanical and hydraulic shear. This ensures that it is completely dispersed and agglomerate-free.

-

Stage 3

Stage 3

The product is pumped back to the process vessel by the self-pumping action of the machine. Once powder addition is complete, a short period of recirculation completes the process.

The Advantages

Using a high shear mixer in place of a simple stirrer or agitator for this application has the following advantages:

- Thickening effect of the alginate is maximized, increasing the yield of raw materials. Products may be reformulated using reduced amounts of alginate, lowering raw materials costs.

- Dramatically reduced processing times eliminates the risk of unintentional temperature rise caused by long mixing times.

- No need for premixing the alginate with other ingredients as it can be added directly into the vessel or powder feed hopper.

- Agglomerate-free mix.

- Operator error during powder addition is virtually eliminated.

- Powder can be incorporated despite the increase in viscosity.

- Greater uniformity between batches.

There are a range of mixers for this application, the selection of which is dictated by the batch size, viscosity of the end product, and grade and percentage of gum used.

High Shear Batch Mixers

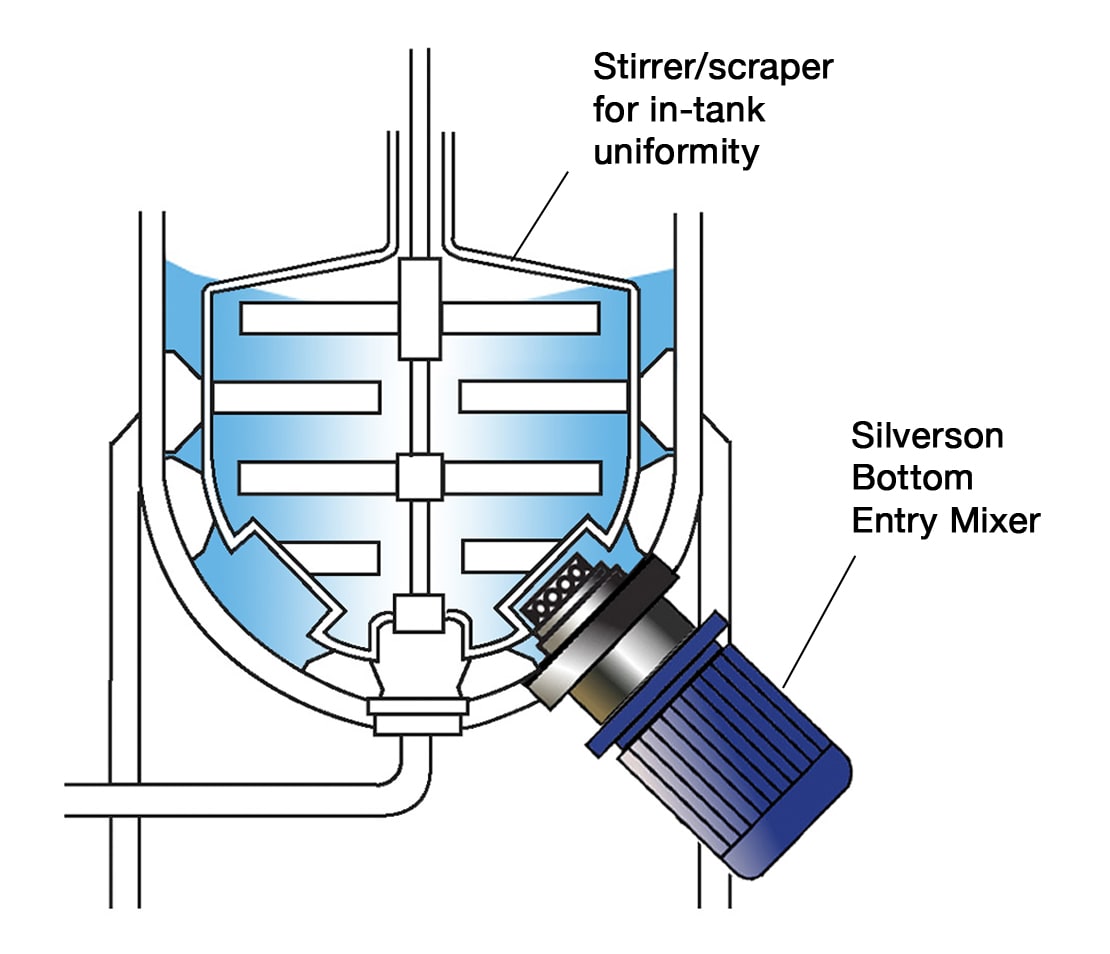

- Can be used alone for lower viscosity recipes or in conjunction with a scraper unit for higher viscosities (as shown)

- Suitable for batches up to 400 US gallons

- Many units can be used on mobile floor stands

- Small units available for R&D and pilot production

- Easily cleaned

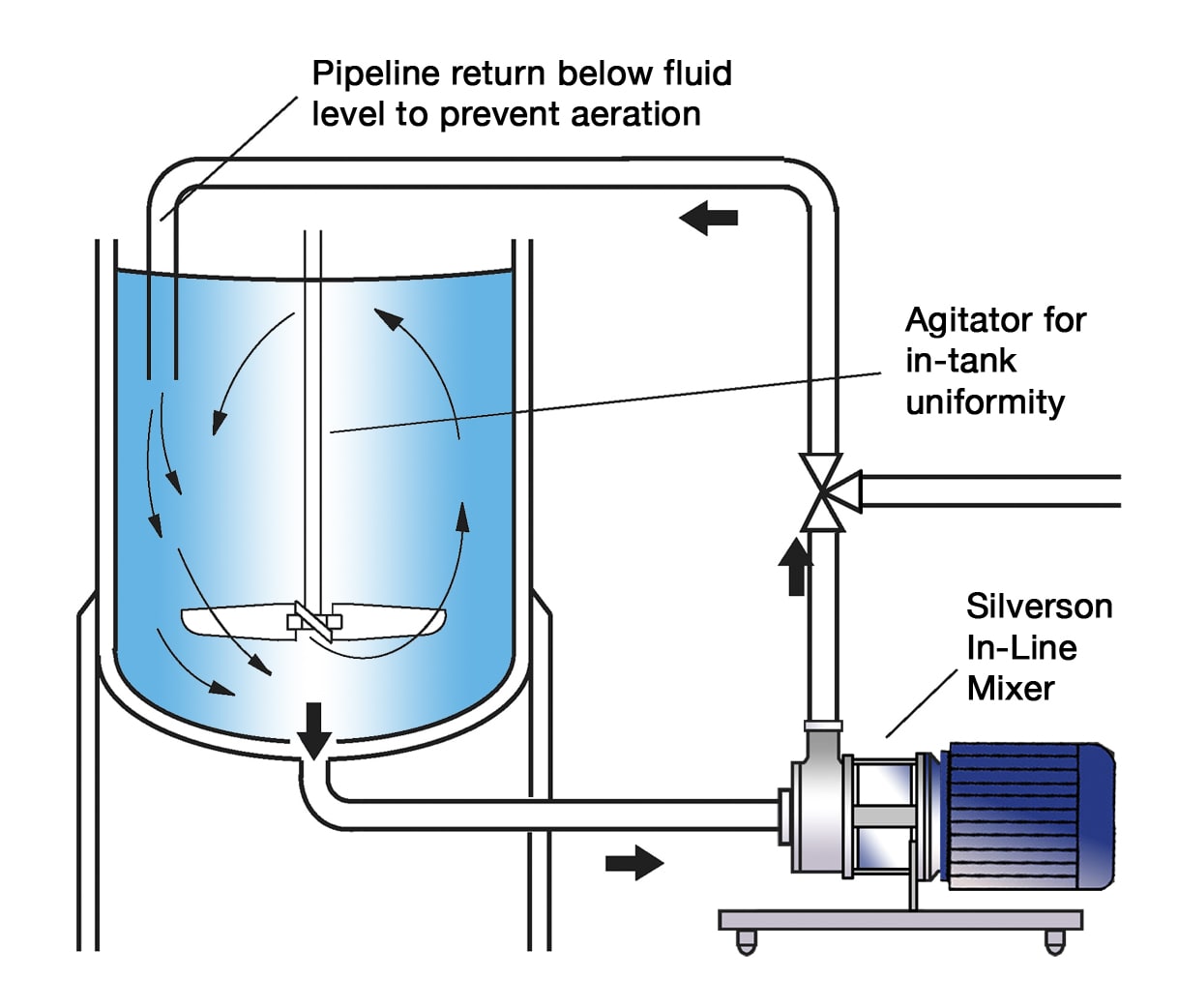

High Viscosity In-Line mixers

- Specially designed to process viscous products

- Capable of hydrating higher concentrations of alginate than standard Silverson In-Line mixers

- Self-pumping, no need for an additional pump even when processing highly viscous products

- Easily retrofitted to existing process

- Minimized aeration

- Ultra Sanitary construction

- Can be used to discharge vessel

Silverson Flashmix

- Ideal for rapidly dispersing large volumes of powder

- Suitable for higher viscosity mixes

- Minimum user input required

- Powder can be added directly into the hopper, no need for premixing

- Controlled powder addition to reduce the formation of agglomerates

- Ideal for larger batches or repeated smaller batches

- Minimized aeration

- Minimized cleaning requirements

- Sanitary models available

High Shear Bottom Entry Mixers

- Suitable for this application when used in conjunction with a scraper unit to maintain in-tank uniformity

- No immersed shaft - reduces cleaning requirements